ACT 1982

INFORMATION

RELEASED UNDER THE OFFICIAL

ACT 1982

INFORMATION

RELEASED UNDER THE OFFICIAL

ACT 1982

INFORMATION

RELEASED UNDER THE OFFICIAL

ACT 1982

INFORMATION

RELEASED UNDER THE OFFICIAL

Version 2 November 2015

Contents

Page

Contents

ACT 1982

1

Survey Details

3

1.1 Background

3

1.2 Survey objective

3

1.3 Scope

3

2

Sampling Handling

5

2.1 Sample Recipt

5

2.2 Sample Forwarding

6

2.3 Batching of Samples

6

2.4 Compositing of Samples

7

3

Testing

7

3.1 Analytical Methods

7

3.2 Testing of Samples

7

INFORMATION

3.3 Measurement Uncertainty

8

4

Data Interpretation and Reporting

8

4.1 Codes

8

4.2 Numerical Issues

8

4.3 Maximum Residue Limits

9

4.4 Residue Definitions (Metabolites/Isomers)

9

4.5 Confirmation of the Identity of Detected Substances

10

4.6 Confirmation and Retesting of Results above MRL

10

4.7 Publication of Use of Results by Laboratories

11

4.8 Electronic Reporting Requirements of Individual MPI Samples

11

5

Quality Assurance

12

5.1 Requirements

12

6

Storage and Retention of Samples and Subsequent Action

13

6.1 Requirements

13

7

Appendix 1 – Glossary

15

8

Appendix 2 – Requirements for Sample Processing

17

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • i

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

1 Survey Details

1.1 BACKGROUND

The Food Residue and Surveil ance Programme (FRSP) was established in 2003 to investigate

residues and contaminants in food for which there was no existing or suitable verification programme.

ACT 1982

The Food Residue and Surveil ance Programme (FRSP) focused on compliance of mainly primary plant

products for agricultural compounds and contaminant residues.

In 2015/2016 the MPI is conducting a survey of fresh and frozen produce for pesticides residues. The

key objective of the survey is to provide assurance for recent pesticide registrations containing new

active ingredients. The aim of this study is to provide assurance to the New Zealand market that newly

registered pesticides are being used in accordance with good agricultural practices and residues are

within set maximum residue limits (MRLs).

In addition the survey aims to provide baseline data on a wide range of pesticides registered for use on

fresh and frozen produce sold within New Zealand. The survey intends to capture both domestic and

imported produce.

The key intent of the survey to gather statistically robust data representative of overall grower

INFORMATION

compliance with pesticide registration restrictions.

1.2 SURVEY OBJECTIVE

The objectives of this survey are to:

• determine if industry are using newly registered agrichemicals correctly;

• monitor pesticide residue levels in produce to ensure they in line with good agricultural practice.

1.3 SCOPE

This document provides the protocol for the survey details the following:

scope of survey;

testing protocol;

sampling plan.

The produce selected for testing during the 2015-2016 year have been determined by the compounds

registered during 2012 and 2014. The equivalent imported crops have been included if applicable.

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 3

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

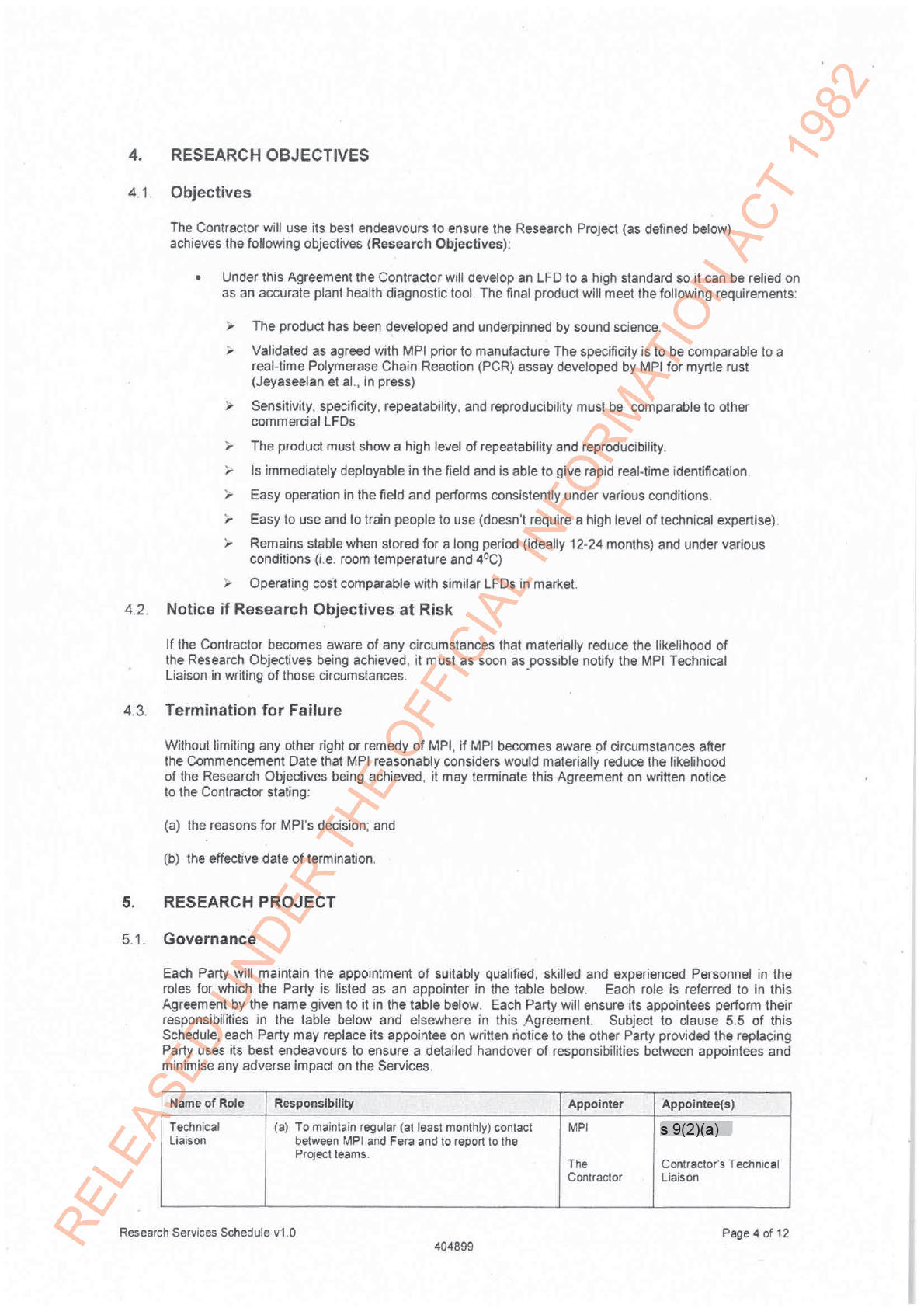

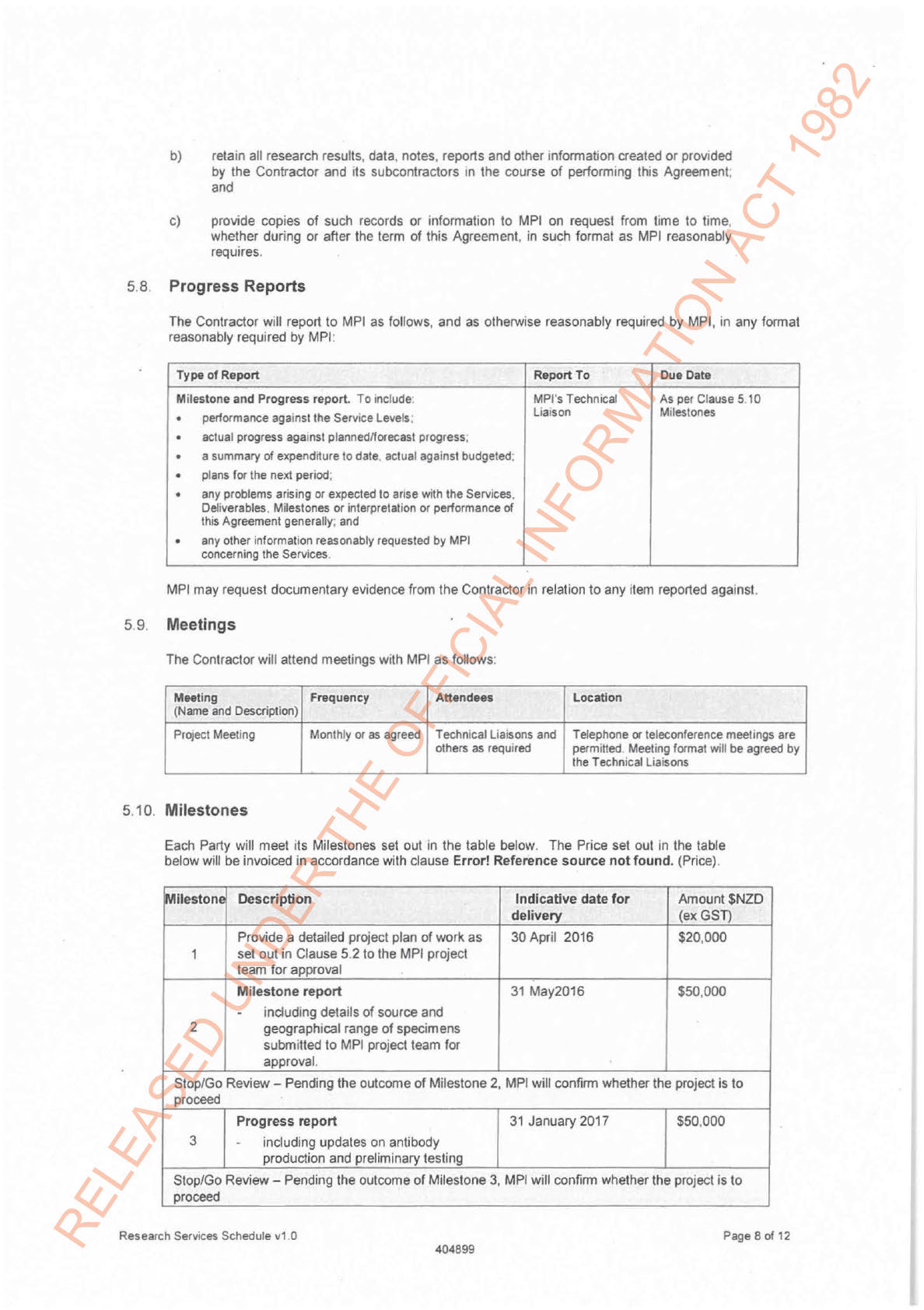

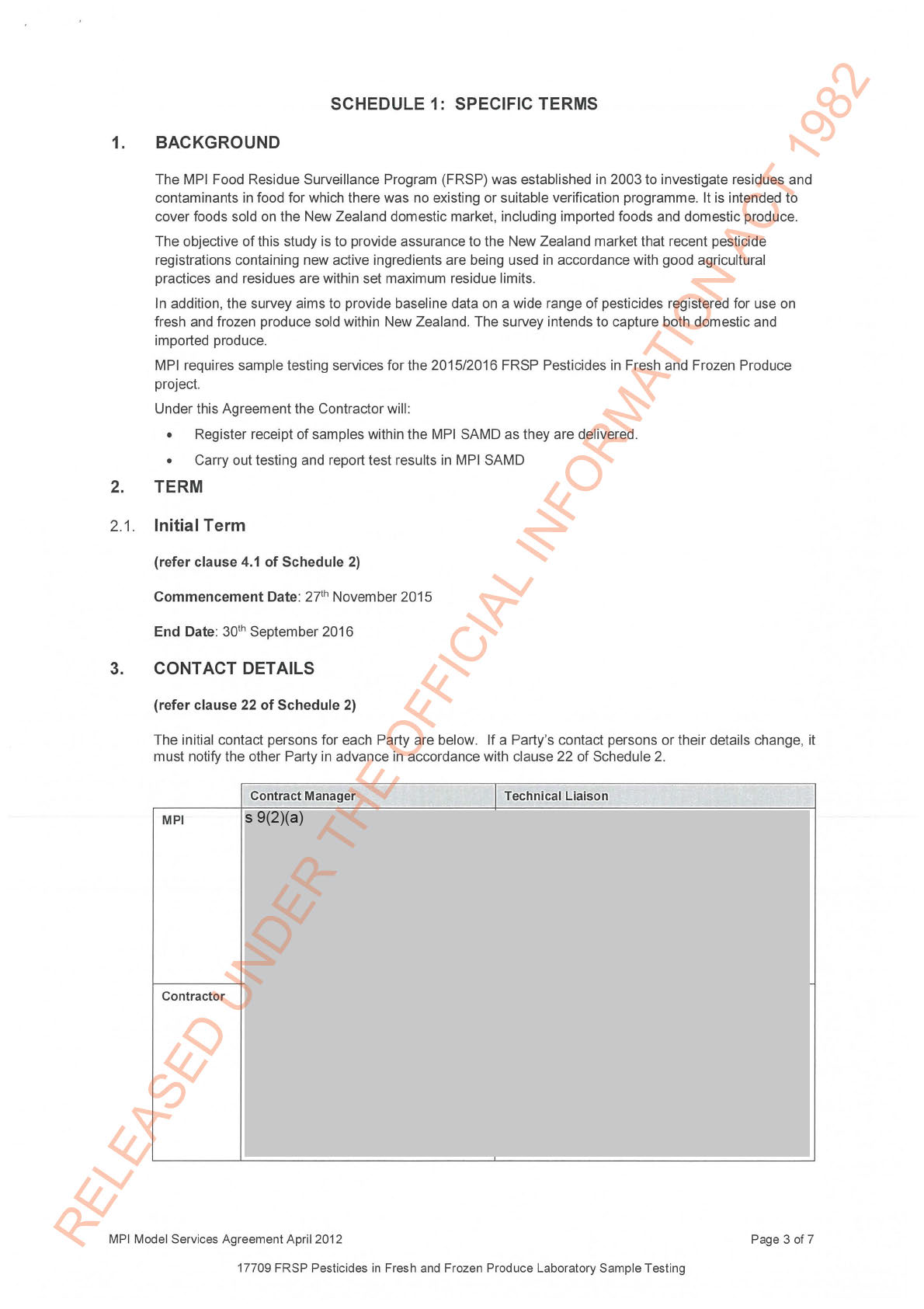

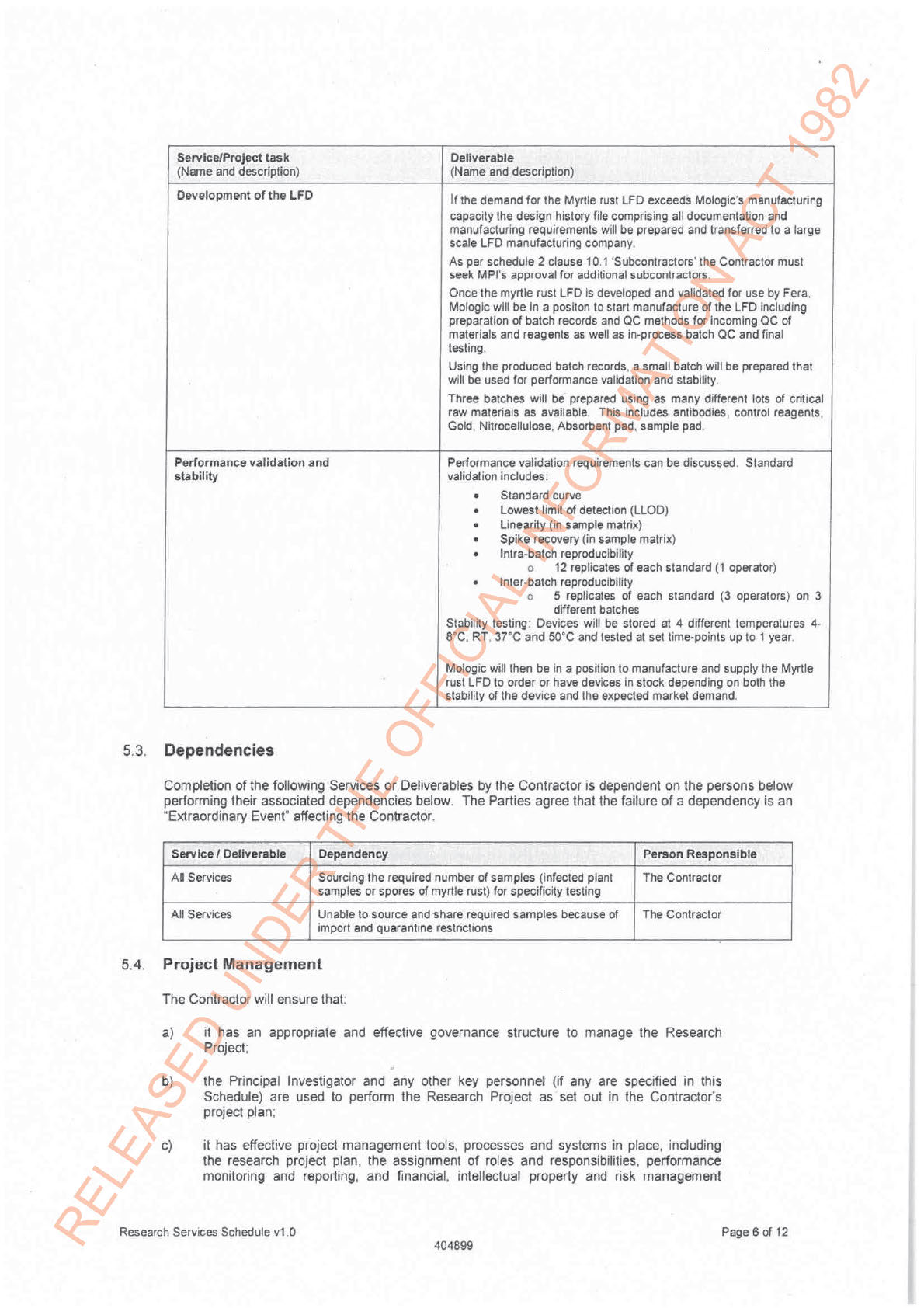

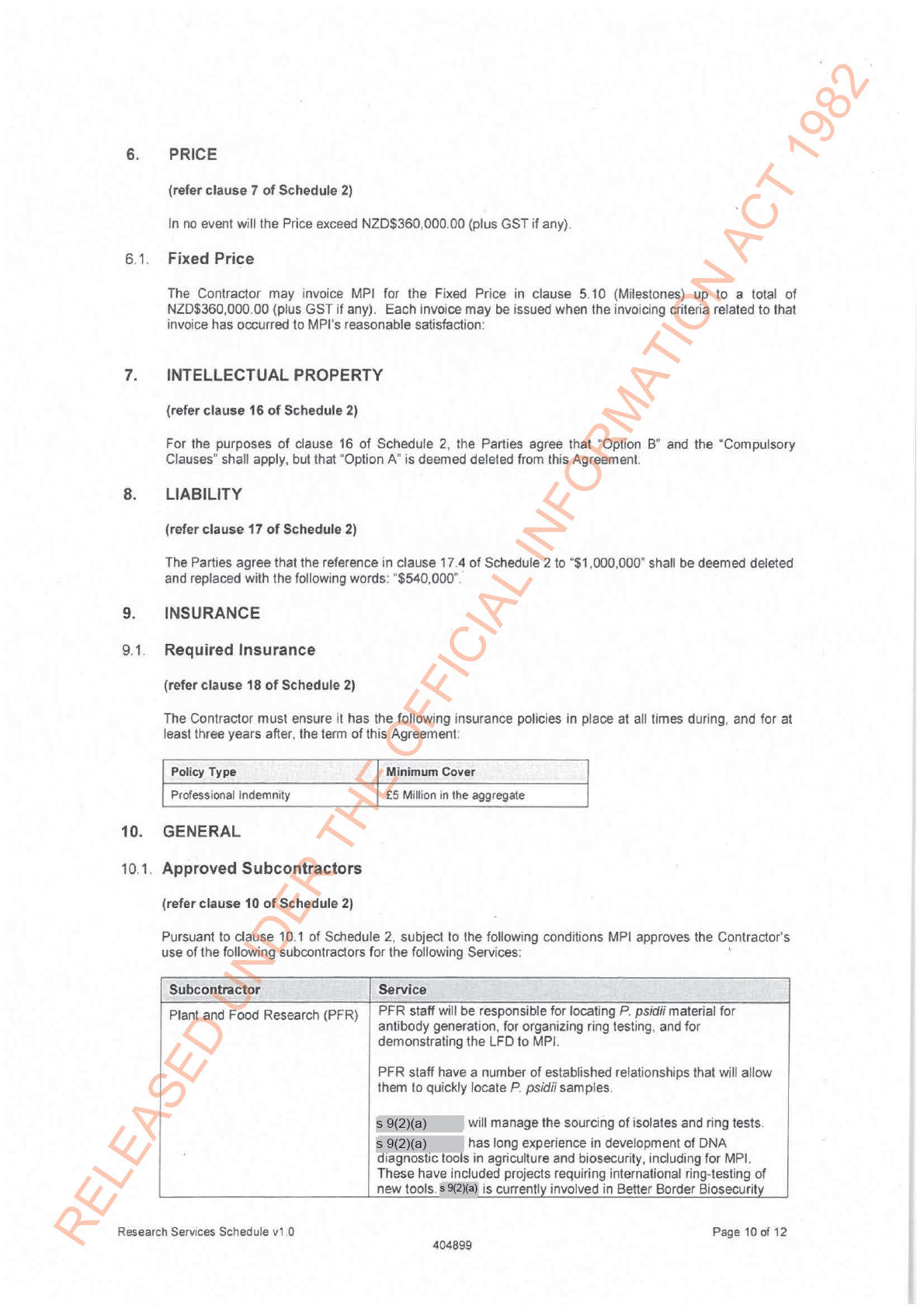

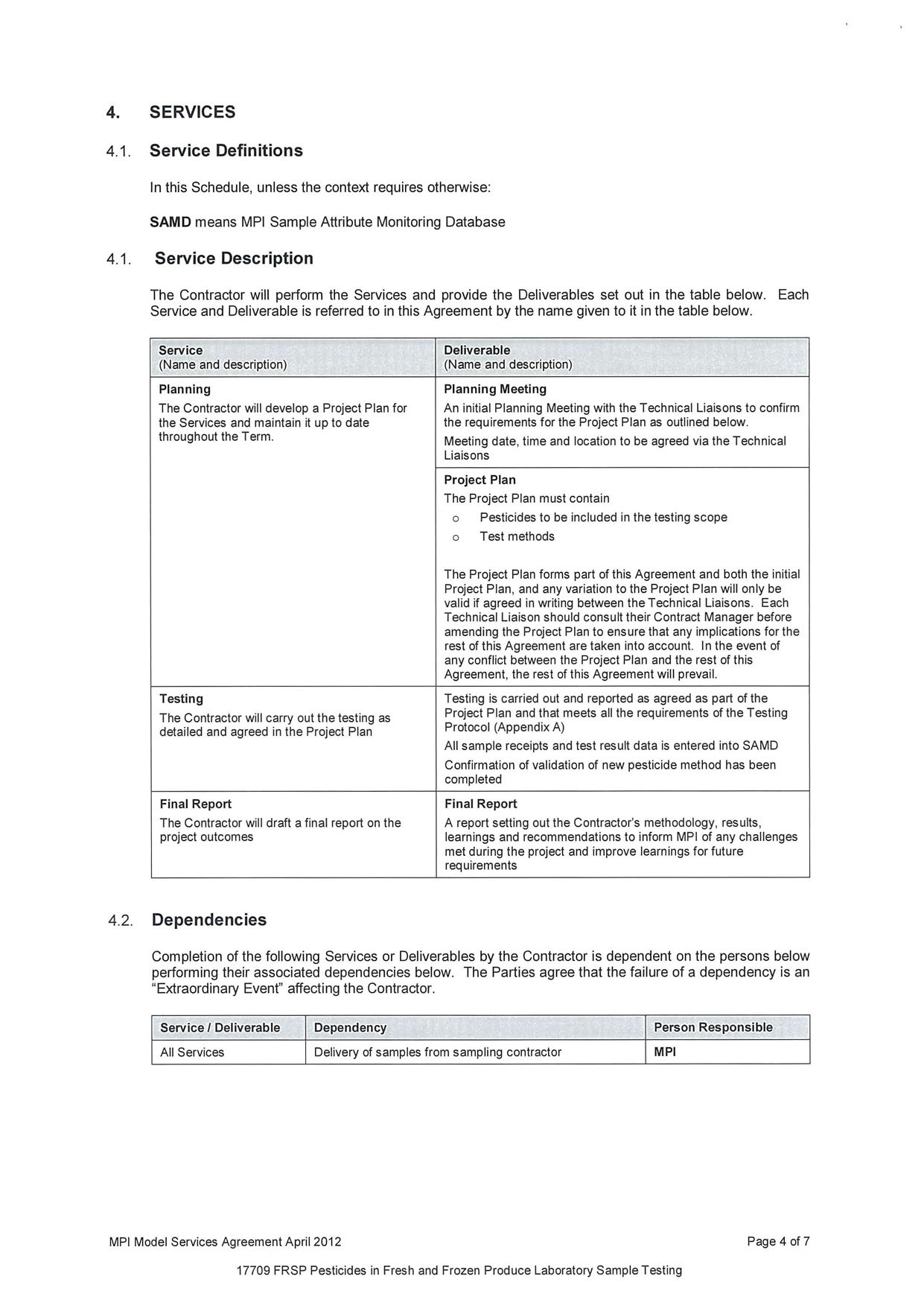

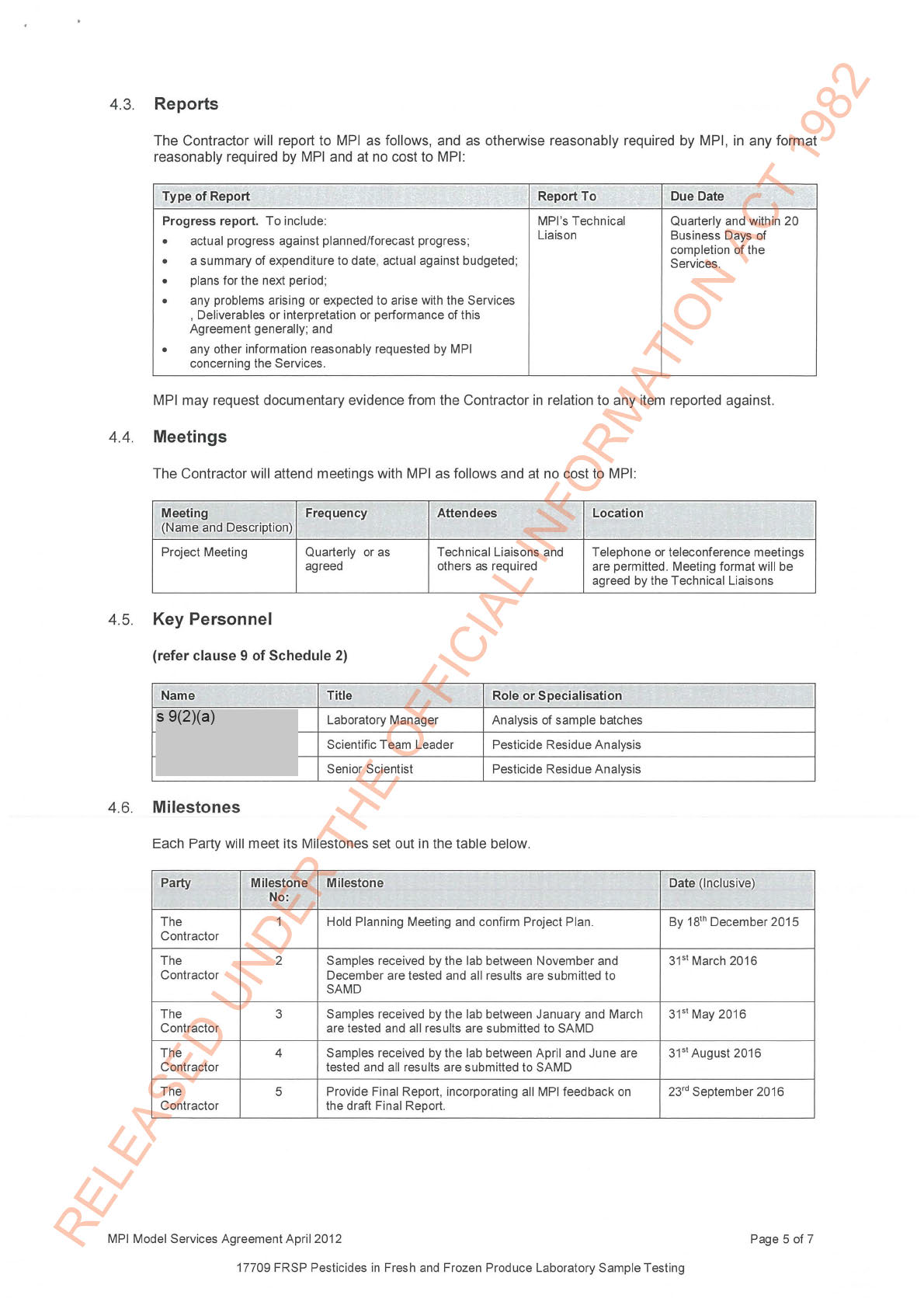

Table 1: Newly registered pesticides that have been identified for this survey

Food

Targeted Pesticide

Brand Names

MRL (mg/kg)

Apples

This list contains three groups of pesticides. The first group is active

Asian greens

ingredients registered within the past two years. The second group is

Barley

pesticides that have current registered uses on one or more of the produce

potentially to be included in the survey. The third group is pesticides that are

of interest to the Ministry for the purposes of gathering baseline data on

ACT 1982

pesticide compliance.

Broccoli

Brussel sprouts

Cabbage

Capsicum

Carrots

Cauliflower

Chilli

Cucumber

Eggplant

Maize

Sweetcorn

Grapes

Kiwifruit

INFORMATION

Lettuce

Okra

Onions

Potatoes

Silver beet

Spinach

Tomatoes

Triticale

Wheat

Winter squash

Zucchini

1.3.1 Scope exclusions

Minimally processed and processed food products are excluded from this survey. Crops that are not for

human consumption are also included. Where sampling occurs at a point where it is stil un-determined

if the product is going to be sold for human consumption, then the product can be sampled (e.g. maize

into silos)

4 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

2 Sampling Handling

2.1 SAMPLE RECIPT

2.1.1 FRSP samples are sent by the samplers to the contracted laboratory’s receival address.

ACT 1982

2.1.2 Samples are randomly collected and are typically dispatched within 5 business days of

collection through the 8 month period from November 2015 to 30 June 2016.

2.1.3 Prior to samples arriving at the laboratory, sampling organisation shall email the laboratory and

MPI, on a weekly basis (or more frequent depending on operations). Sample details such as

product type, quantity shall be included in the email. Where possible the estimated date of

arrival and tracking details are included in the email.

2.1.4 Where possible, samples wil be dispatched by overnight courier to arrive at the laboratory the

following day.

2.1.5 Samples sent from sample collection agencies are normally dispatched by overnight courier

Monday to Thursday to arrive at the laboratory on Tuesday to Friday. In some circumstances

dispatches may arrive on Saturdays.

INFORMATION

2.1.6 Upon receipt of sample boxes or containers at the laboratory, the sample must be checked to

ensure it is intact and sample integrity has not be comprised.

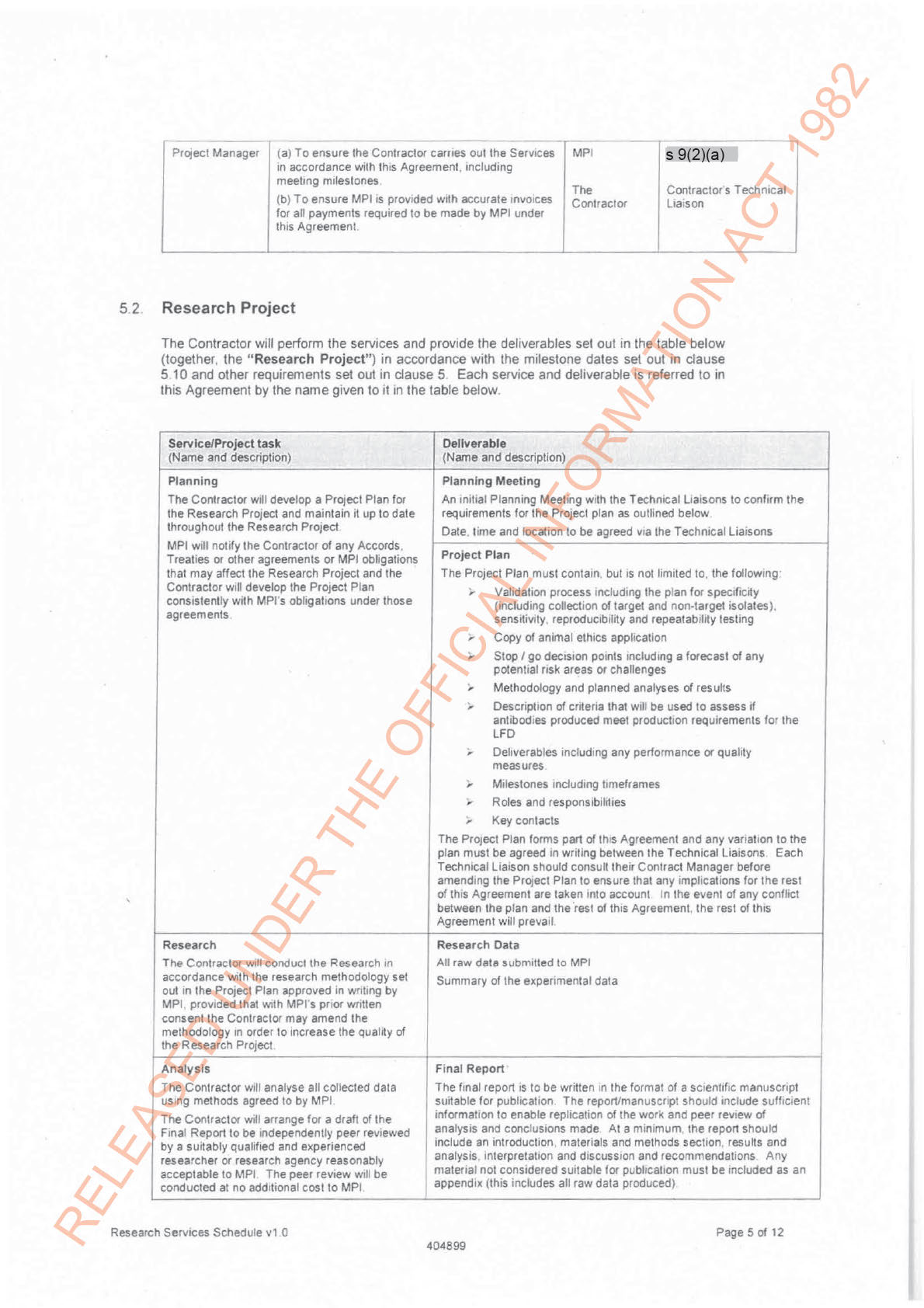

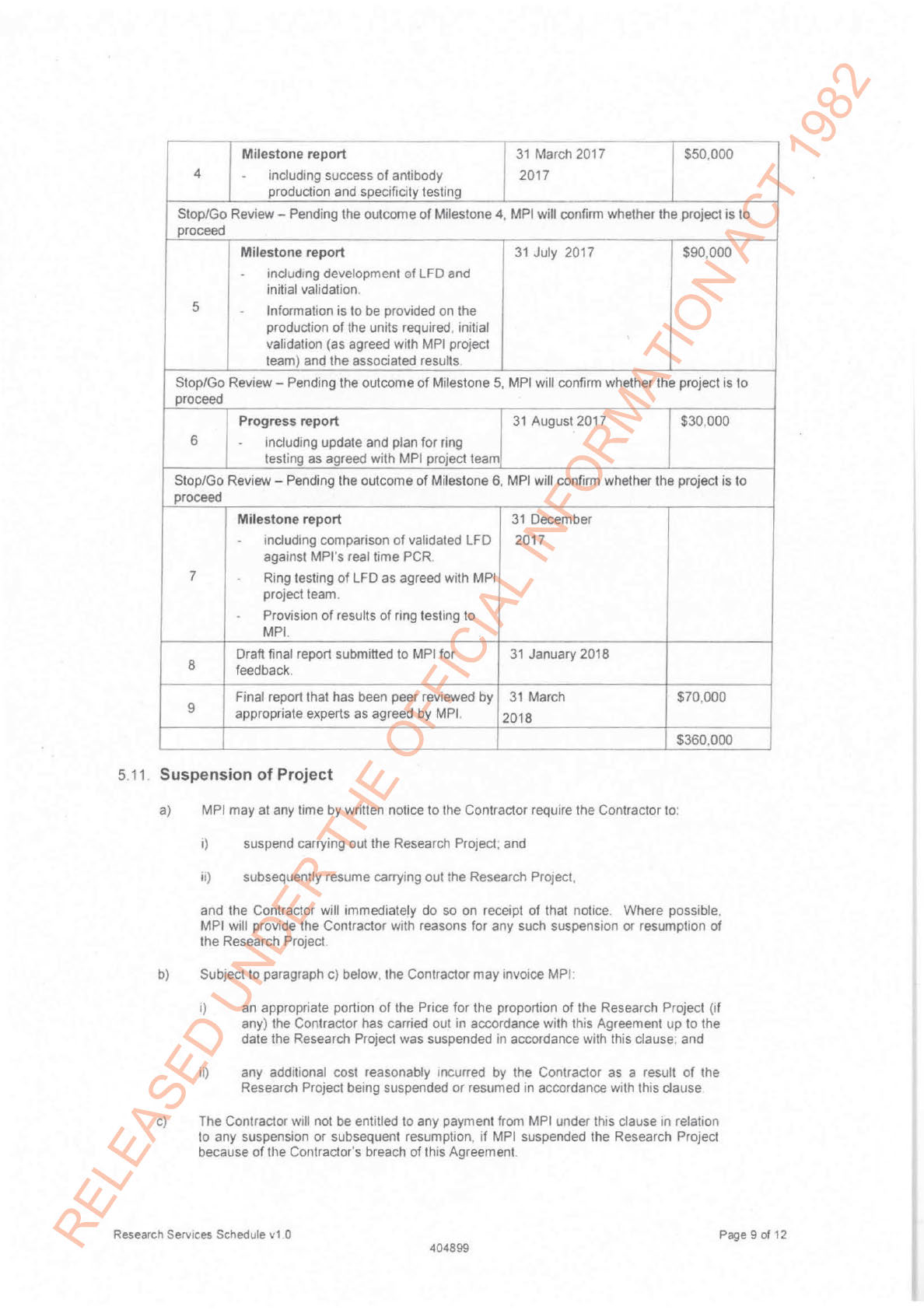

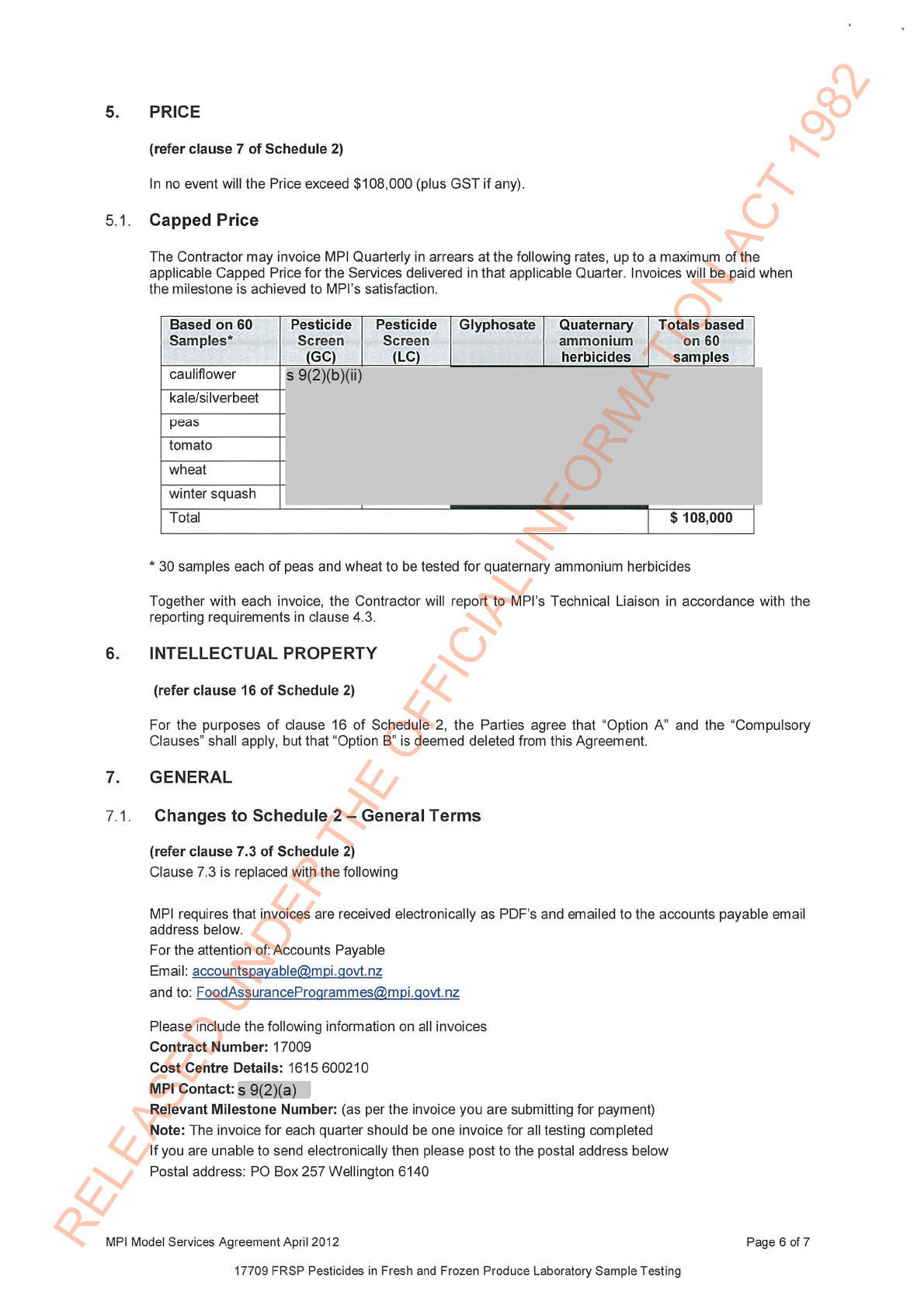

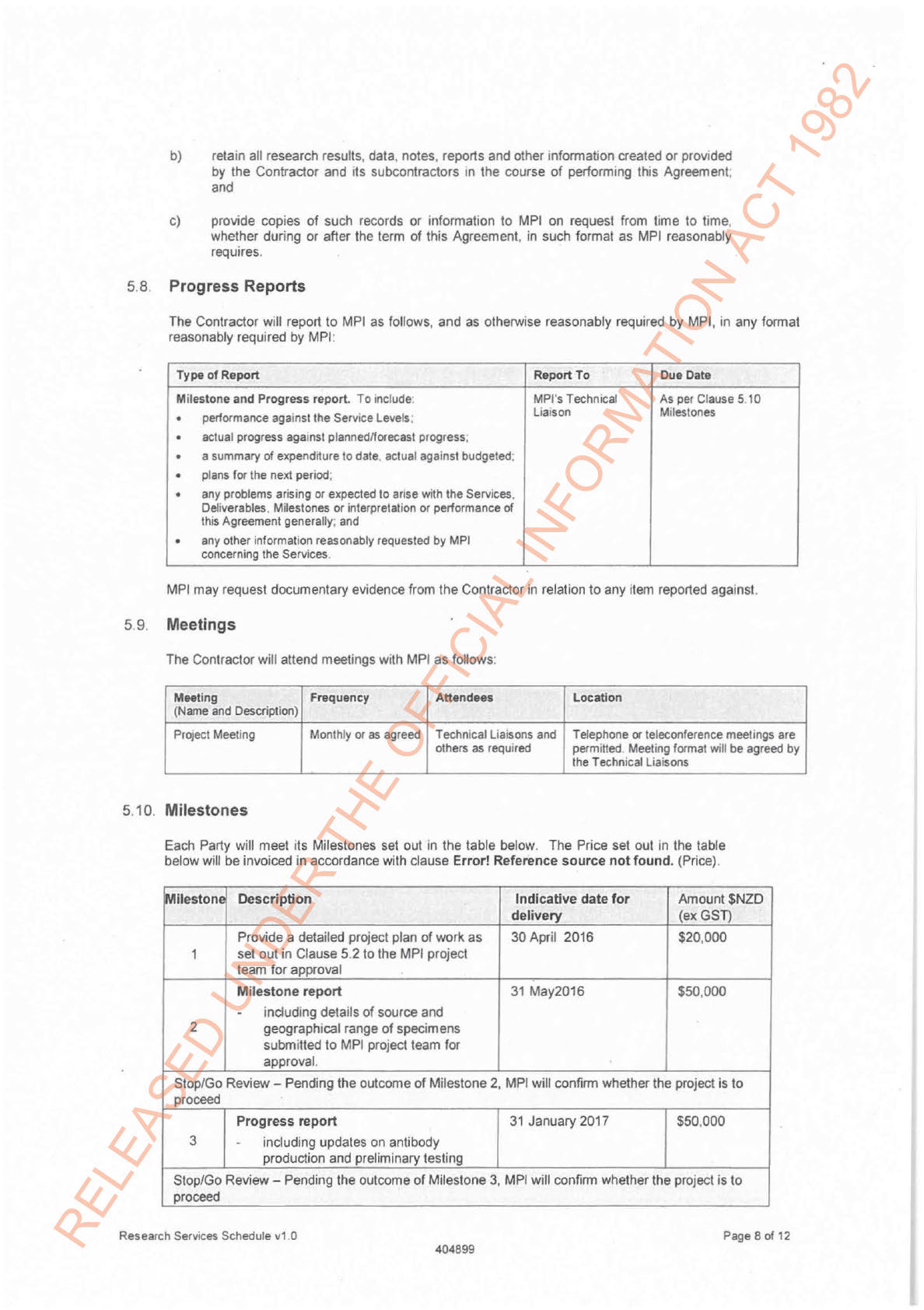

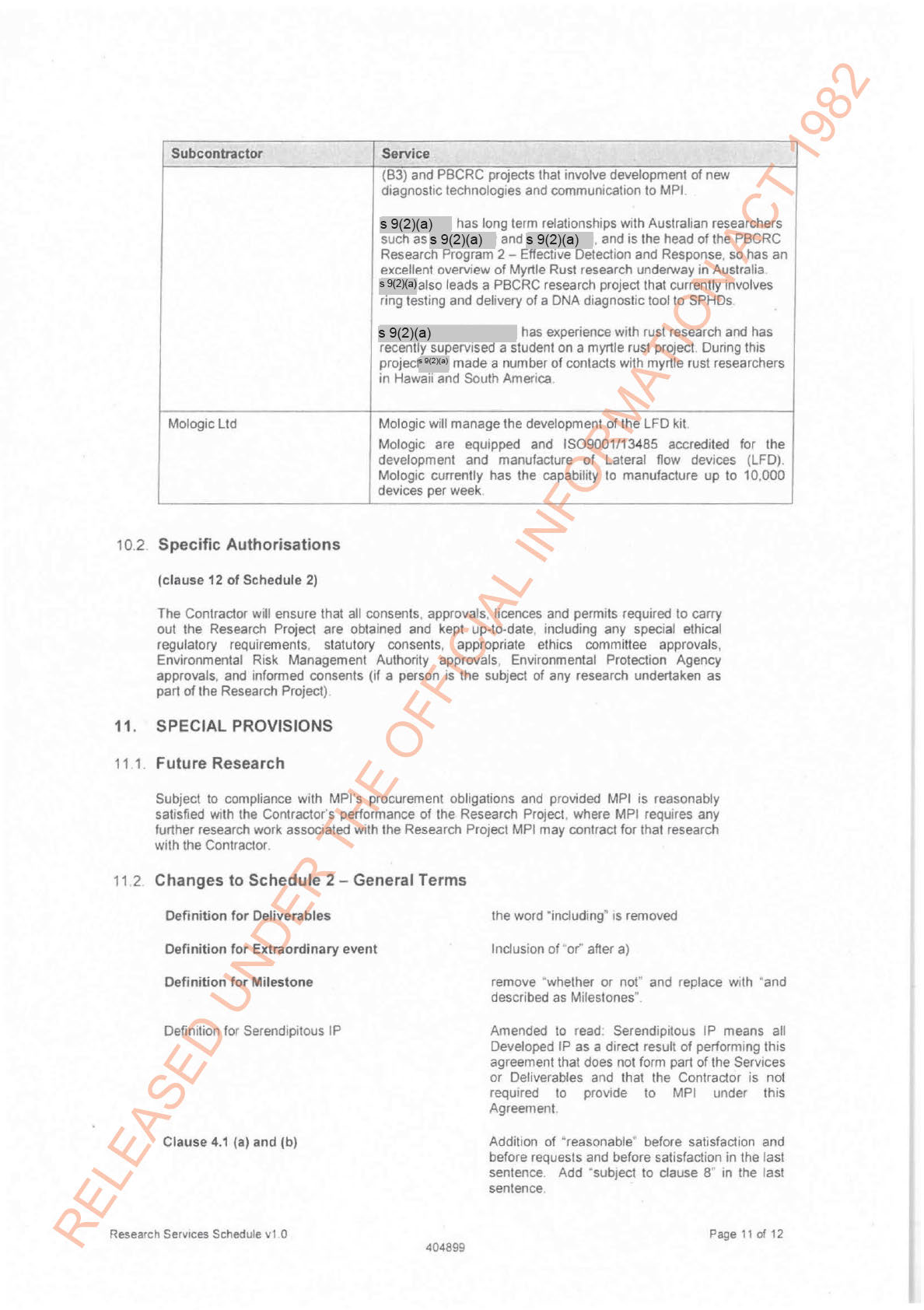

Reason for cancelling the

Description

analysis request

Inadequate sample size

Sample integrity breach due to lack of matrix provided

Incorrect matrix or test

Sample integrity breach due to incorrect matrix

provided, or test requested

Laboratory issue

Laboratory unable to perform analysis

Not suitable for analysis

Various sample condition issues (evidence of spoilage)

Sample incorrectly contained

Sample integrity breach due to sample not packaged in

any sample container or packaging opened, damaged

or unsealed

Other

Unexpected non-conformance

2.1.7 If the samples have been comprised and are deemed unsuitable for testing, email MPI at

[email address] and the sample must be held pending advice from

MPI.

Sample matrix

Minimum acceptable sample condition on receipt at

laboratory

Fruit, vegetables and cereal grains Room temperature, no evidence of spoilage or cross-

contamination

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 5

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

2.1.8 Each sample wil have a sample label attached to or visible through, the outer plastic bag when

it arrives at the laboratory. The sample label wil contain a unique sample number, as allocated

by the database, for example FRSP25.

2.1.9 The sample number (e.g. FRSP25) is the unique number identifying that sample in the MPI

SAMD database for the survey.

2.1.10 If any information on the sample label is dif erent to the sample or database (for example the

ACT 1982

sample recorded in the database is tomato when the physical sample presented is silver beet),

email MPI at [email address] and the sample must be held pending

advice from MPI.

2.1.11 Laboratories must log all samples received and report results into the MPI SAMD database

(http:/ residues.maf.govt.nz/residues). Information on using the MPI database wil be provided

to the contracted laboratories.

2.1.12 If the laboratory did not receive the stated samples after 3 business days, the laboratory wil

inform sampling organisation and MPI for re-sampling.

2.1.13 If the laboratory has received samples that are not suitable for testing, the laboratory wil inform

sampling organisation and MPI for re-sampling.

2.1.14

INFORMATION

The sampling organisation wil liaise with MPI to get suitable substitute sample(s) and re-submit

samples to laboratory.

2.2 SAMPLE FORWARDING

2.2.1 There may on occasion be a need for MPI to have samples or sub-sampled portions of samples

to be forwarded to a dif erent contracted laboratory. These samples must conform to the

requirement in the table above when they arrive at the next laboratory. Samples are to be

repackaged and forwarded, no later than 24 hours after notification from MPI. Unless part of

MPI’s contract for services, any additional costs of repackaging samples are to be separately

invoiced to MPI.

2.3 BATCHING OF SAMPLES

2.3.1 Contracted laboratories may wish to delay commencement of the testing of individual or small

numbers of samples received in an attempt to process a batch of samples together. The holding

of samples for batching results must not result in any sample’s results being reported outside

the applicable milestone/deliverable dates unless advised by MPI. Generally the

milestone/deliverable dates wil enable suitable batches to be formed.

2.3.2 If there is a problem in completing an individual sample in a batch, email MPI at

[email address] and the samples must be held pending advice from

MPI

6 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

2.4 COMPOSITING OF SAMPLES

2.4.1 Compositing of samples is not allowed unless specifically advised by MPI.

3 Testing

ACT 1982

3.1 ANALYTICAL METHODS

3.1.1 Innovation and method refinement is encouraged, subject to certain controls. Unless otherwise

agreed by MPI, the contracted laboratory wil use the same analytical method as agreed in the

MPI contract for services.

3.1.2 The analytical method used must be identical (in all significant respects) to that referred to in

the validation specifications held by the laboratory and for which the laboratory holds current

IANZ or equivalent accreditation or MPI approval. The laboratory is required to maintain IANZ or

international equivalent accreditation of the analytical method used to analyse MPI samples.

Exceptions to this may be approved by MPI, for example interim accreditation based on national

accreditation body recognised proficiency in analytical instrumental techniques, such as IANZ

2.70.

3.1.3

INFORMATION

MPI must be notified of any issues with accreditation of these methods following the relevant

accreditation body’s audits.

3.1.4 While laboratories are encouraged to evaluate changes to methodology that may improve the

performance of the method, details of any proposed change (including all relevant validation

data) are not to be implemented for MPI samples without first receiving approval from MPI.

3.1.5 Following agreement of a change, MPI may assign a new assay number and assay code(s) for

use in reporting test results using the revised method where any of the following apply:

• new analytes have been included in the Programme for the first time that would not have been

previously tested for, or reported;

• the number of analytes required to be tested for, has changed;

• the laboratory method limits of detection (LODs), limit of quantification (LOQ) or limits of

reporting (LORs) have changed;

• the methodology (e g. extraction / clean-up techniques, detection systems, or use of an

surrogate standards has been modified to the extent that the substances covered, LODs,

LOQs, LORs, recoveries, precision, accuracy etc. have been significantly altered.

3.1.6 When requested, laboratories must provide technical information relating to details of the testing

procedures of their contract(s). At any stage during the contract term further information may be

required.

3.2 TESTING OF SAMPLES

3.2.1 Samples sent to MPI contracted laboratories wil generally require a degree of processing prior

to testing. The following information is provided as a guide to the types of samples that may be

received and the preparation processes required.

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 7

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

3.3 MEASUREMENT UNCERTAINTY

3.3.1 Laboratories operating under this contract and accredited by IANZ (or international equivalent,

or under MPI approval) for a particular test, are expected to determine the measurement

uncertainty associated with their results.

4

ACT 1982

Data Interpretation and Reporting

4.1 CODES

4.1.1 Laboratories must use the MPI assay number and assay code(s) when reporting results to the

MPI database. The assay number and assay code(s) wil be provided to the contracted

laboratories.

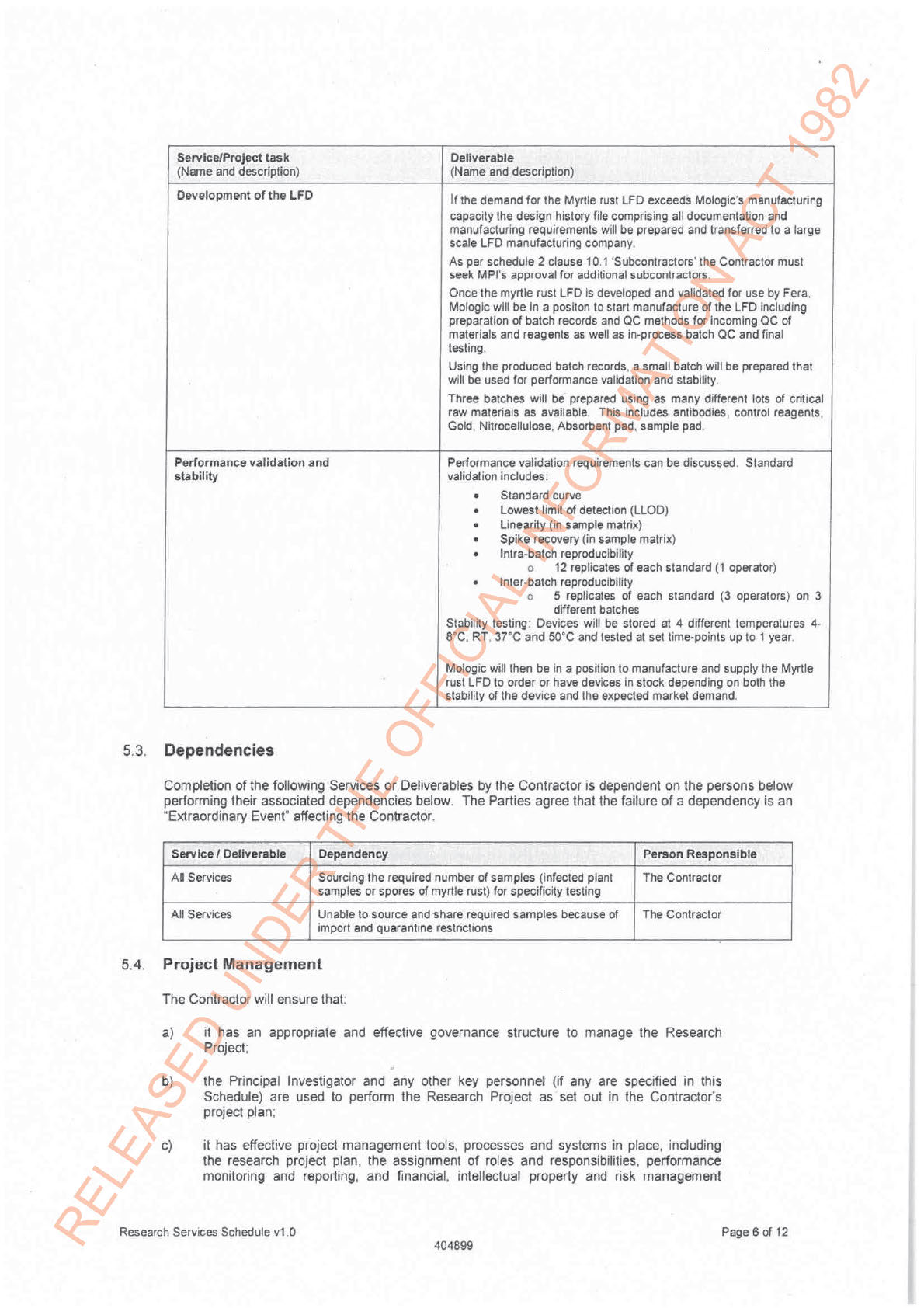

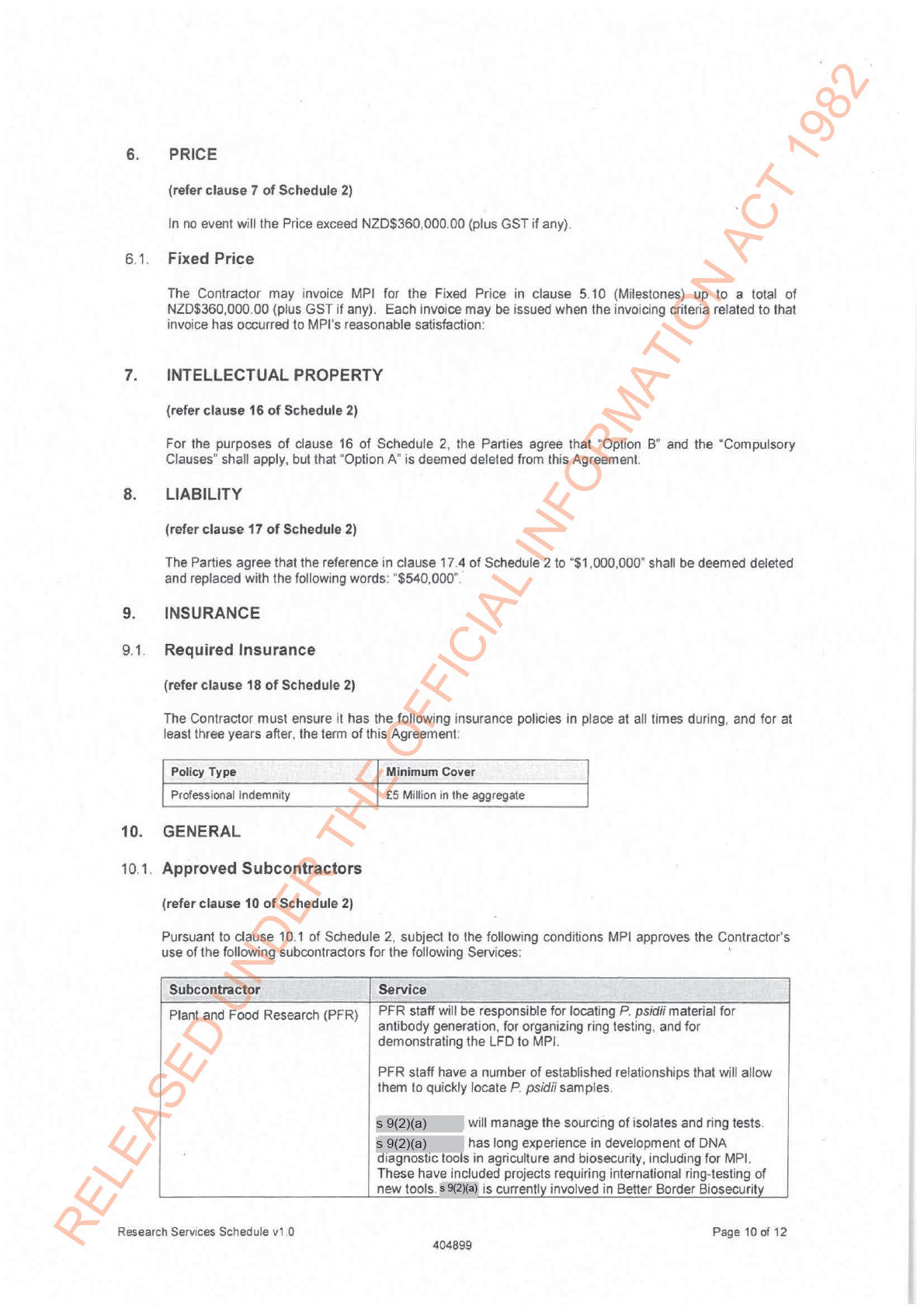

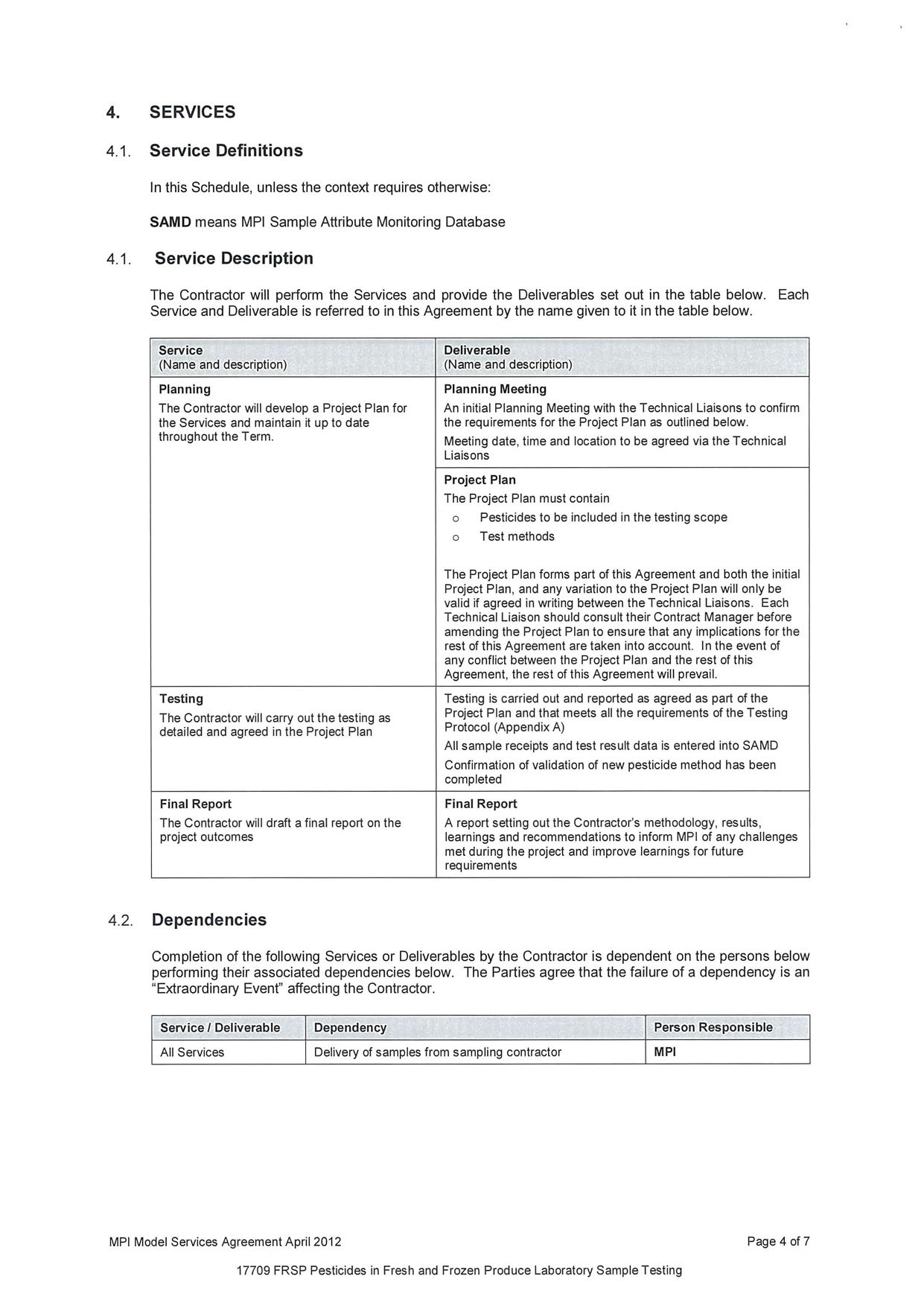

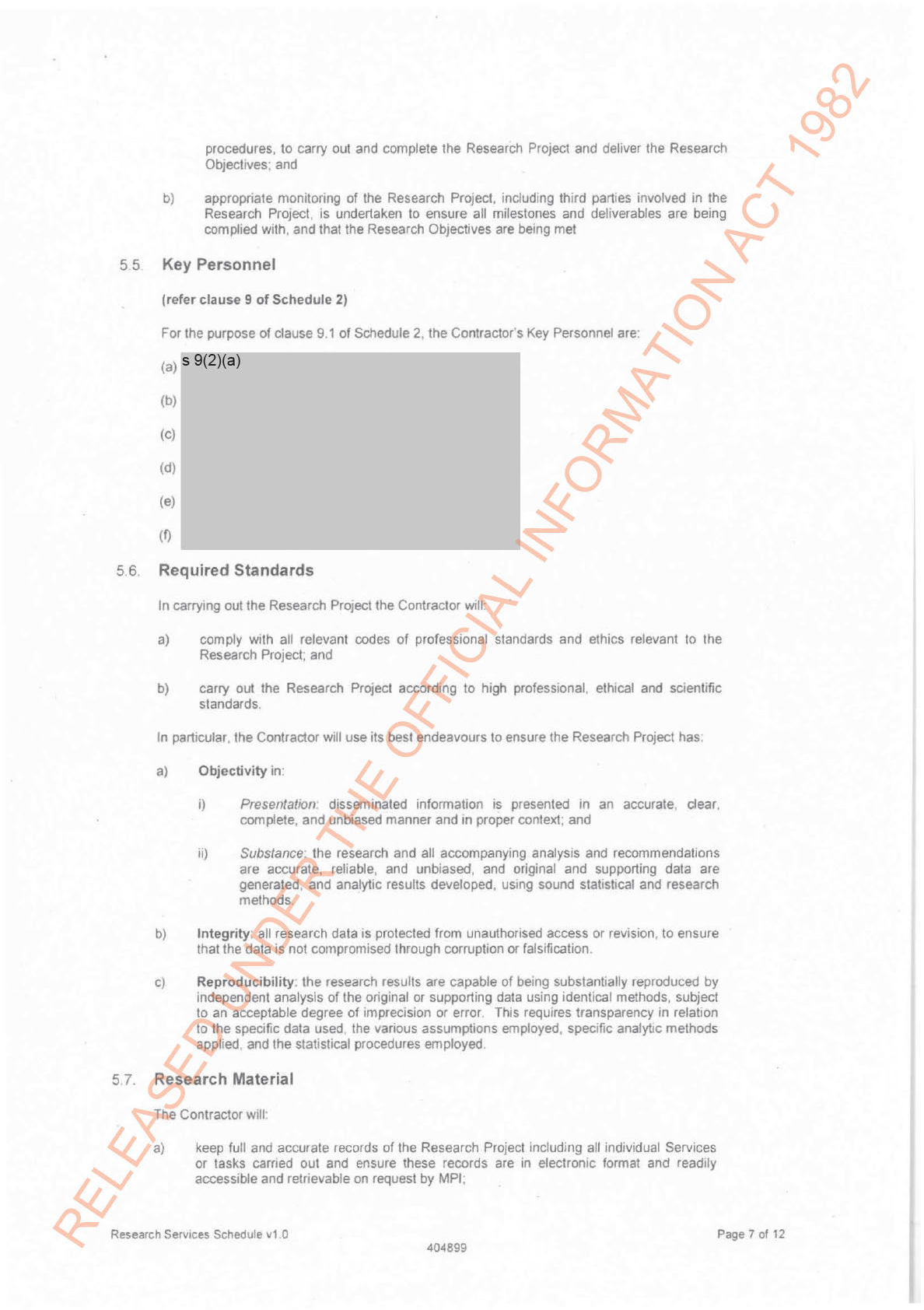

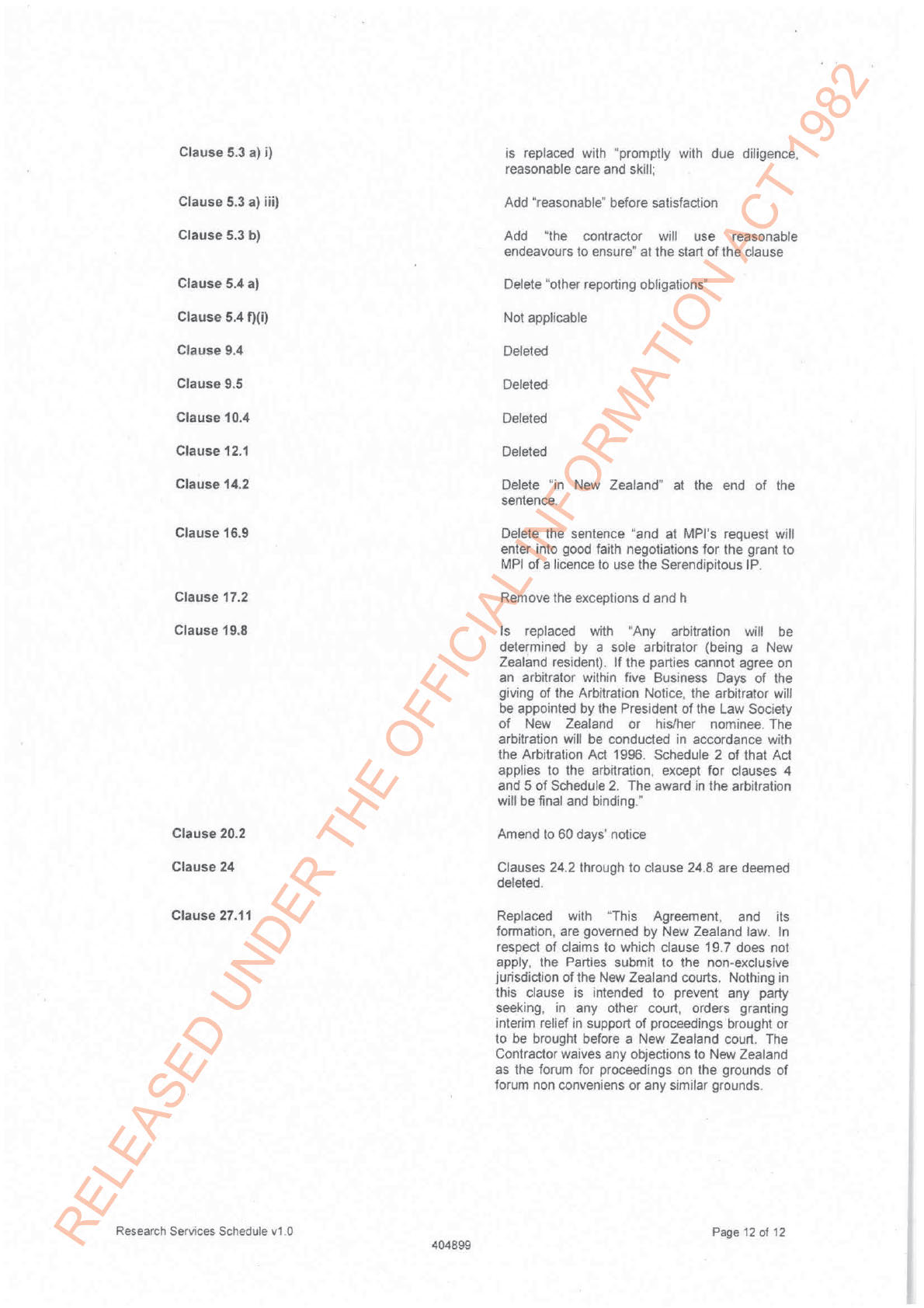

Assay

Laboratory Contaminant

Applicable Product types

Number Code

240

MRGL05

Multiscreen pesticides

All

241

GLYP01

Glyphosate

Wheat and peas

242

DIQT02

Quaternary ammonium herbicides Wheat and peas

INFORMATION

4.2 NUMERICAL ISSUES

4.2.1 It is essential to maintain uniformity in reporting results of residue levels. In general, results

above the LOR and <10 mg/kg should be rounded to two significant figures. Results ≥10 mg/kg

may be rounded to three significant figures or to a whole number. Reporting limits should be

rounded to 1 significant figure at <10 mg/kg and two significant figures at ≥10 mg/kg. In any

case, the rounding of results should never lead to a dif erent decision being taken with regard to

the exceedance of a legal limit such as the MRL. Thus, rounding to significant figures should be

done after the final calculation of the result.

4.2.2 Where a residue has been identified and quantified using a single test portion, and the residue

does not exceed the MRL, the reported result should be that measured using the detection

technique considered to be the most accurate. Where results are obtained by two or more

equally accurate techniques, the mean value may be reported.

4.2.3 In general, residues data do not have to be adjusted for recovery when the mean recovery is

within the range of 70-120%. If residues data are adjusted for recovery, then this must be

stated. Exceedances of the MRL must be supported by individual recovery results (from the

same batch) within the range of the mean recovery (70-120%) ± 2 x RSD, at least for the repeat

confirmatory analyses. If recovery within this range cannot be achieved, enforcement action is

not necessarily precluded, but the risk of relatively poor accuracy must be taken into account. It

is then highly recommended to correct for recovery, preferably by using standard addition or

isotopically labelled standards, for all cases of MRL exceedances.

4.2.4 Where two or more test portions have been analysed, the arithmetic mean of the most accurate

results obtained from each portion should be reported. Where good comminution and/or mixing

of samples has been undertaken, the RSD of replicate results of the test portions should

normally not exceed 30% for residues significantly above the LOQ. Close to the LOQ, the

8 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

variation may be higher and additional caution is required in deciding whether or not a limit has

been exceeded.

4.2.5 Laboratories must accumulate evidence that recoveries in the stated range can be achieved

consistently. If recoveries fall outside an acceptable limit of 3 x RSD and/or for any other non-

conformance relevant to the processing and testing of MPI samples, the cause must be

investigated. A report, including the corrective action taken, must be emailed to MPI at

[email address].

ACT 1982

4.2.6 A contracted laboratory must report quantitative results for all substance detected at or above

the laboratory’s method LOR to the MPI database. Qualitative results must be reported in

accordance with MPI database requirements which consist mainly of user selection of reporting

options. Information on using the MPI database wil be provided to the contracted laboratories.

4.2.7 ‘Traces’ are not to be reported on the MPI database. A ‘trace’ refers to the detection of a

substances at a concentration between the laboratory’s method LOD and LOR that can be

identified consistent with SANCO/12571/2013 substance identification requirements but not

quantified with the same degree of certainty as detections at or above the laboratory’s LOR.

‘Traces’ are to be reported on a separate spreadsheet, containing the sample number,

laboratory number, substance name, laboratory LOD, LOQ & LOR, estimated substance

amount, units.

INFORMATION

4.2.8 In cases where a laboratory is confident that it has detected a substance below its LOD, those

identity is consistent with the acceptance criteria specified in SANCO/12571/2013, the result is

not to be reported on the MPI database.

4.3 MAXIMUM RESIDUE LIMITS

4.3.1 The Maximum Residue Limits (MRLs) are set out the New Zealand (Maximum Residue Limits

of Agricultural Compounds) Food Standards 2015.

4.3.2 The MRLs that relate to the substance in the MPI FRSP survey are regularly reviewed and may

be updated during the contract period. If this occurs, laboratories contracted for MPI work

affected wil be advised of changes that are relevant to their contracts and consulted on any

issues which this raises.

4.4 RESIDUE DEFINITIONS (METABOLITES/ISOMERS)

4.4.1 Unless otherwise agreed with MPI, where a residues definition for a particular substance

involves metabolites/isomers, laboratories must measure and report the individual analytes

detected separately and report the sum of the parent/metabolites/isomers. Calculation of the

sum of the individual components is based on the residue definition. These wil be either a sum

of individual components or a sum of individual component expressed as the parent residue.

4.4.2 The laboratory must take into consideration the residue definition in relation to the MRL and

then apply the appropriate confirmation/re-analysis and reporting procedures.

4.4 3 In the case of synthetic pyrethroids, individual isomers should be reported where possible and

in a way that would reflect the comparison of the likely isomer enriched commercial product. For

example, if all relevant peaks are detected in a GC run in the retention time window of

cyhalothrin, then the result should be reported as cyhalothrin (sum of isomers). However, if only

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 9

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

a single major peak is detected in the same retention time window which is known to

correspond to lamba-cyhalothrin, the lamba-cyhalothrin should be reported and not cyhalothrin

(sum of isomers).

4.5 CONFIRMATION OF THE IDENTITY OF DETECTED SUBSTANCES

4.5.1

ACT 1982

The criteria outlined in the EU guidelines (SANCO/12571/2013) form the basis for MPI

requirements regarding a laboratory’s method capabilities for the detection and confirmation of

MPI FRSP for this contract. MPI requires the confirmation of the identity of detected substances

in samples to be consistent with the requirements for the confirmation of substances as outlined

in the SANCO/12571/2013.

4.5.2 Laboratories awarded the contract(s) should note that these requirements apply to the testing of

samples dispatched to laboratories during the contract period. A full copy of this document can

be made available in electronic form on request to MPI.

4.5.3 Confirmatory methods for substance would preferably be based on mass spectrometry and

incorporate the concept of identification points to fulfil the criteria outlined in the

SANCO/12571/2013 guidelines.

INFORMATION

4.6 CONFIRMATION AND RETESTING OF RESULTS ABOVE MRL

4.6.1 For all programmes where the concentration of a substance is > MRL (or default) a repeat test

(in duplicate) must be undertaken on a separate portion of the original sample to confirm both

the concentration and identification of the substance.

4.6.2 If the identity has been confirmed, the two quantitative results must be averaged and the

average reported to the MPI database and emailed to MPI. If the two results dif er by more than

30% of the average value, the average should stil be reported to MPI and in addition email MPI

at [email address].

4.6.3 In the process of confirmation and re-analysis, in instances where a laboratory chooses to re-

analyse >2 separate sample portions, the average of the original result and each of the

individual sample portion quantitative results must be averaged and the average report to MPI,

unless this is inappropriate, i.e. where individual sample portion tests are performed via dif erent

instrumental techniques, each with dif erent analytical method parameters.

• e.g. original residue result = 0.076 mg/kg, which is greater than the residue’s MRL

• first replicate (separate sample portion) confirmatory result – 0.065 mg/kg

• second replicate (separate sample portion) confirmatory result – 0.060 mg/kg

• average residue result = 0.067 mg/kg

• 30% of average residue result = 0.0201 mg/kg

• acceptable replicate residue result range = 0.0469 to 0.0871 mg/kg

• the three results 0.076, 0.065 and 0.060 mg/kg are within the acceptable replicate

range so there is no requirement to notify MPI of an issue with variability of results.

• the average residue result to be reported to MPI is 0.067 mg/kg

10 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

4.6.4 For confirmed results exceeding MRLs must be reported to the MPI database and emailed to

MPI at [email address]. Notification to the MPI database and MPI

must be within 1 business day following confirmation of the result.

4.6.5 A copy of all analytical and internal quality control results must be retained by the laboratory,

and made available for MPI inspection or auditing on request, for a period of three years.

ACT 1982

4.7 PUBLICATION OF USE OF RESULTS BY LABORATORIES

4.7.1 Individual sample details are confidential. A laboratory may not release or publish the results of

MPI work without the writ en permission of MPI. Any copyright or other intellectual property

associated with the results is the exclusive property of MPI.

4.8 ELECTRONIC REPORTING REQUIREMENTS OF INDIVIDUAL MPI SAMPLES

4.8.1 Sample receipt details shall be entered within three working days of laboratory sign-off of

sample receipt.

4.8.2 Results for each sample are to be electronically or manually entered into the MPI database. The

address of the database is http:/ residues.maf.govt.nz/residues. Notification to the MPI

INFORMATION

database must be within 1 business day following confirmation of the result. Access to the live

site wil be provided by MPI upon request. Information on using the MPI database wil be

provided to the contracted laboratories.

4.8.3 Laboratories must email MPI [email address] if persons with MPI

database access are no longer assigned to this role (in order to cancel their access rights to the

database). Notification must be within 1 business day of the person ceasing this activity.

4.8.4 Test results shall be entered within 1 working day of signoff.

4.8.5 Laboratories must use the MPI assay number and assay code(s) for residues and contaminants

when reporting results to the MPI database. These assay codes for the FRSP wil be sent

directly to the contracted laboratories.

4.8.6 Laboratories must nominate a contact person, telephone number and email address for

handling of database result reporting queries

4.8.7 Data entry errors such as duplicate electronic records or faulty electronic records shall be

notified to the MPI [email address].

4.8.8 The database saves any modifications made to an electronic sample record. When amending a

sample record, what is amended and the reason for change shall be indicated in the comment

box titled “Reason for Change”. Changes are unable to be made without including a comment in

the “Reason for Change”

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 11

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

5 Quality Assurance

5.1 REQUIREMENTS

5.1.1 MPI requires that contracted laboratories operate and document a quality control system.

Documentation should include information on the laboratories arrangements and frequency with

respect to monitoring analytical variance, the testing of standards, matrix blanks, recoveries and

ACT 1982

duplicate samples, calibration, identify the extent to which internal standards, certified reference

materials as well as intra- and inter-laboratory check samples are incorporated.

5.1.2 Laboratories in this contract are required to participate in international ILCP programmes where

these align with the programmes in this contract applicable to that laboratory.

5.1.3 A contracted laboratory must keep, and make available to MPI, any record relevant to the MPI

contract(s) which it holds.

5.1.4 Laboratories participating in the contract are expected to cooperate with MPI staff in maintaining

the integrity of the system.

5.1.5 The contracted laboratory must notify MPI of any changes that may adversely affect the

function or performance of, or decrease the efficiency of, the laboratory services provided to

MPI, for example relocation of the laboratory facility. INFORMATION

5.1.6 Al laboratories awarded MPI contracts may be required to host laboratory visits/audits during

the contract period. The aim wil be for MPI staff to visit each laboratory at least once a year.

5.1.7 A list of all analysts & their roles in the testing of animal product (non-dairy) samples should be

maintained by the laboratory and may be viewed by MPI during an on-site audit.

5.1.8 It is anticipated that the FRSP survey is likely to be subjected to scrutiny by a large and varied

number of stakeholders. Because of this rigorous and robust laboratory practices be required.

At a minimum it is proposed laboratories must:

• hold ISO/IEC 17025:2005 accreditation as a facility;

• hold IANZ (or international equivalent) specific method accreditation for the tests

required in similar matrixes, or alternatively be able to demonstrate previous experience

and competency with the tests;

• in most instances, achieve a limit of reporting (LOR) of 0.01 mg/kg;

• achieve a linear range of LOR to 10 x LOR or MRL;

• report of quantitative results greater than LOR;

• conducted confirmatory testing by analysis techniques capable of complying with the

criteria for compound identification as SANCO/12571/2013;

• report, where possible, all results as per the residue definition specified in the New

Zealand (Maximum Residue Limits of Agricultural Compounds) Food Standards 2015;

• report results in mg/kg units on an ‘as received’ basis;

12 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

• provide a laboratory QC report outlining the recovery (amount found / amount fortified)

of the spiked duplicate in each testing batch;

• store securely original laboratory samples for a period of not less 6 week after the issue

of the final laboratory test report in suitable storage container, protected from light and

pests damage at a temperature of less -10°C;

• if required by MPI arrange for samples to be tested at a second laboratory; ACT 1982

• if required provide chromatograms and supporting data for detections greater than

MRL;

• make all data available for review if required during any MPI visits to the laboratory.

Minimum requirements of within batch quality control:

• standard calibration curve covering bracketing the linear range;

• matrix-matched blank;

• reagent blank;

•

INFORMATION

low recovery spike at LOR;

• high recovery spike;

• one sample duplicate per batch;

• one ‘blind’-spiked sample duplicate per batch.

Confirmation of all detections, satisfying the identification criteria set out by

SANCO/12571/2013, greater than half of MRL by the following procedure:

• re-testing of the original sample in duplicate;

• calculation of the amount found wil be based on four point matrix-matched calibration

curve (fortified with 1, 2, 3 & 5 times amount expected);

6 Storage and Retention of Samples and Subsequent Action

6.1 REQUIREMENTS

6.1.1 Al original samples are to be retained for a minimum of six weeks from the date of issuing the

final survey results so that, if requested, a complete retest may be undertaken.

6.1.2 Al samples found to contain residues in excess of the MRL must be retained for a minimum of

six weeks after the issue of the final survey report. Writ en (email) approval must be obtained

from MPI before such samples are destroyed or sent for disposal.

6.1 3 Al samples should be stored in an appropriate manner and in a way that ensures identity is

retained and to minimise the possibility of cross-contamination i.e. each sample should be

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 13

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

stored with its original label and wrapped in a bag that is intact, and preferably with the MPI

label used to identify the sample to the laboratory.

6.1.4 Al samples should be stored securely. Al samples must be stored in a locked freezer with

access to the freezers restricted and monitored.

6.1.5 If samples are stored in a freezer or refrigerator, the freezer or refrigerator should contain a

temperature monitoring device (e.g. max/min thermometer, electronic temperature logger)

ACT 1982

which should be checked on a regular basis to ensure that the correct temperatures are

maintained.

INFORMATION

14 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

7 Appendix 1 – Glossary

Term

Definition

Batch (analysis)

For extraction, clean-up and similar processes, a batch is a series of

samples dealt with by an analyst (or team of analysts) in parallel,

usually in one day, and should incorporate at least one recovery

determination. For the determination system, a batch is a series

undertaken without a significant time break and which incorporates all

ACT 1982

relevant calibration determinations (also referred to as an “analysis

sequence”, a “chromatography sequence”, etc.). A determination

batch may incorporate more than one extraction batch.

Blank

(i) Material (a sample, or a portion or extract of a sample) known not to

contain detectable levels of the analyte(s) sought. Also known as a

matrix blank.

(i ) A complete analysis conducted using the solvents and reagents

only; in the absence of any sample (water may be substituted for the

sample, to make the analysis realistic) Also known as a reagent blank

or procedural blank.

Comminution

The process of reducing a solid sample to smaller fragments by

crushing, pulverising, grinding, etc

Confirmation

Confirmation is the combination of two or more analyses that are in

agreement with each other (ideally, using methods of orthogonal

INFORMATION

selectivity), at least one of which meets identification criteria).

The nature and extent of confirmation required for a positive result

depends upon importance of the result and the frequency with which

similar residues are found.

Assays based on an ECD tend to demand confirmation, because of

their lack of specificity.

Mass spectrometric techniques are often the most practical and the

least equivocal approach to confirmation.

False negative

A result wrongly indicating that the substance concentration does not

exceed a specified value.

False positive

A resu t wrongly indicating that the substance concentration exceeds a

specified value.

Identification

Is a qualitative result from a method capable of providing structural

information (e.g., using mass spectrometric (MS) detection) that meets

acceptable criteria for the purpose of the analysis.

The process of generating of sufficient evidence to ensure that a result

for a specific sample is valid. Substances must be identified correctly

in order to be quantified.

Limit of detection (LOD)

The lowest concentration of a substance at which positive

identification can be achieved with reasonable and/or previously

determined confidence in a defined matrix using a specific analytical

method

Limit of quantification (LOQ) The lowest concentration of a substance at which positive

identification and quantification can be achieved with reasonable

and/or previously determined confidence in a defined matrix using a

specified analytical method

Limit of reporting (LOR)

The lowest level at which residues wil be reported as absolute

numbers. It is equal to, or higher than the LOQ.

The Lowest Calibration Level (LCL) must be equal to or lower than the

calibration level corresponding to the Limit of reporting (LOR).

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 15

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

Lowest Calibration Level The lowest concentration (or mass) of substance with which the

(LCL)

determination system is successfully calibrated, throughout the

analysis batch.

Matrix-matched calibration Calibration intended to compensate for matrix effects and acceptable

interference, if present. The matrix blank (see “blank”) should be

prepared as for analysis of samples. In practice, the pesticide is added

to a blank extract (or a blank sample for headspace analysis) of a

matrix similar to that analysed. The blank matrix used may dif er from

ACT 1982

that of the samples if it is shown to compensate for the effects.

However, for determination of residues approaching or exceeding the

MRL, the same matrix (or standard addition) should be used.

Maximum Residue Limit

Maximum Residue Limit is the food standard applicable to domestic

(MRL)

food, as set in the New Zealand (Maximum Residue Limits of

Agricultural Compounds) Food Standards 2015

IANZ

International Accreditation New Zealand

Receipt date

The date on which the sample is received by the laboratory

Report date

The date on which the analyst completes the test and signs off the

result

Sampling date

The date on which the sample was collected

Sample number

The unique sample number allocated to a sample by the MPI

database

Test portion

A representative sub-sample of the test sample, i.e. the portion w

INFORMATION hich

is to be analysed.

Test sample

The laboratory sample after removal of any parts that are not to be

analysed, e.g. stems, adhering soil. It may or may not be comminuted

and mixed before withdrawing test portions.

Trace

A ‘trace’ refers to the detection of a substance at a concentration

between the laboratory’s method LOD and LOR, i.e. the identity can

be confirmed to the criteria outlined in the SANCO/12571/2013 but it

cannot be quantified with the same degree of certainty as detections

at or above the LOR. However, if the laboratory is able to quantify the

result and would record it in its own record keeping system, the result

should also be reported to MPI

16 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

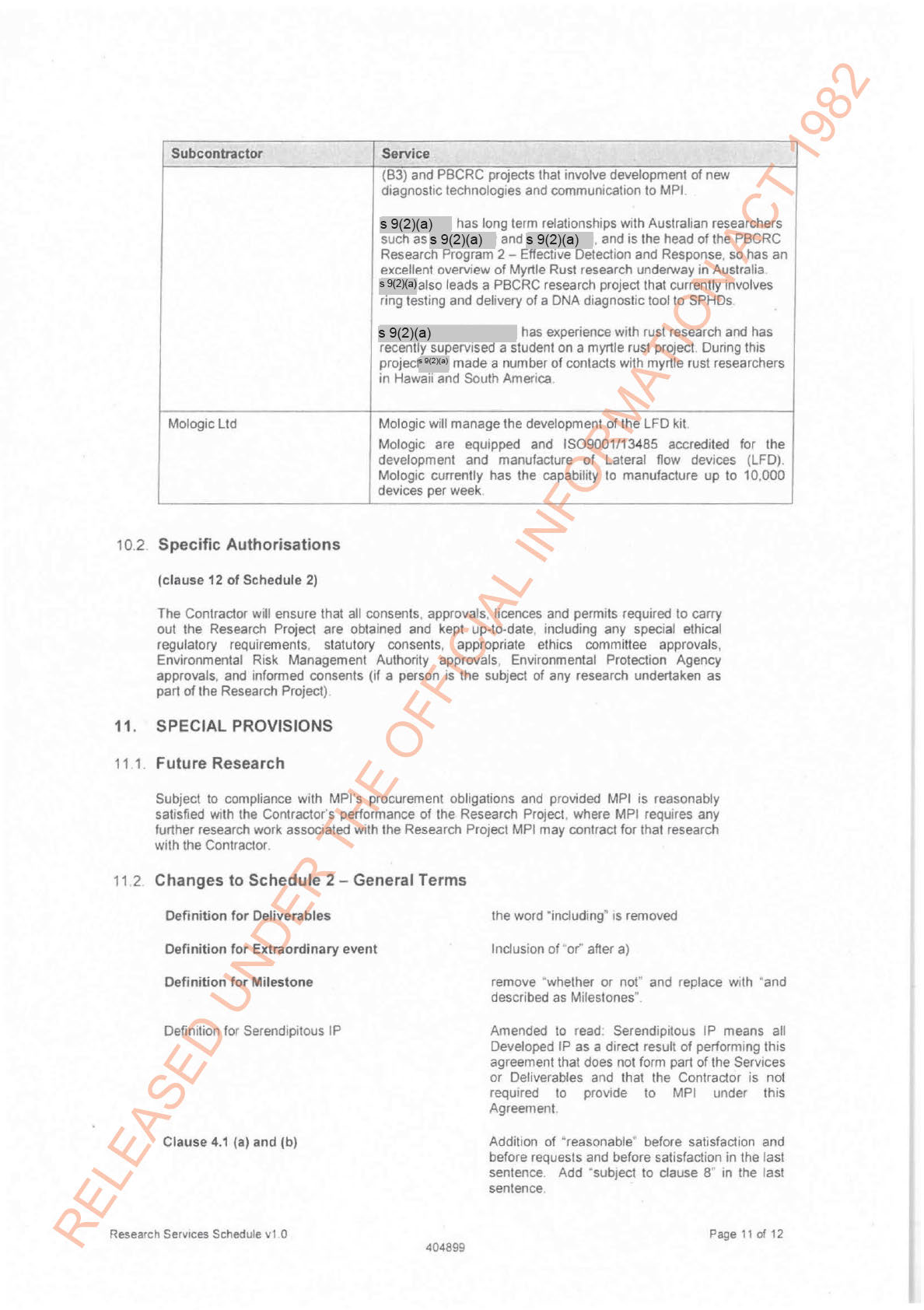

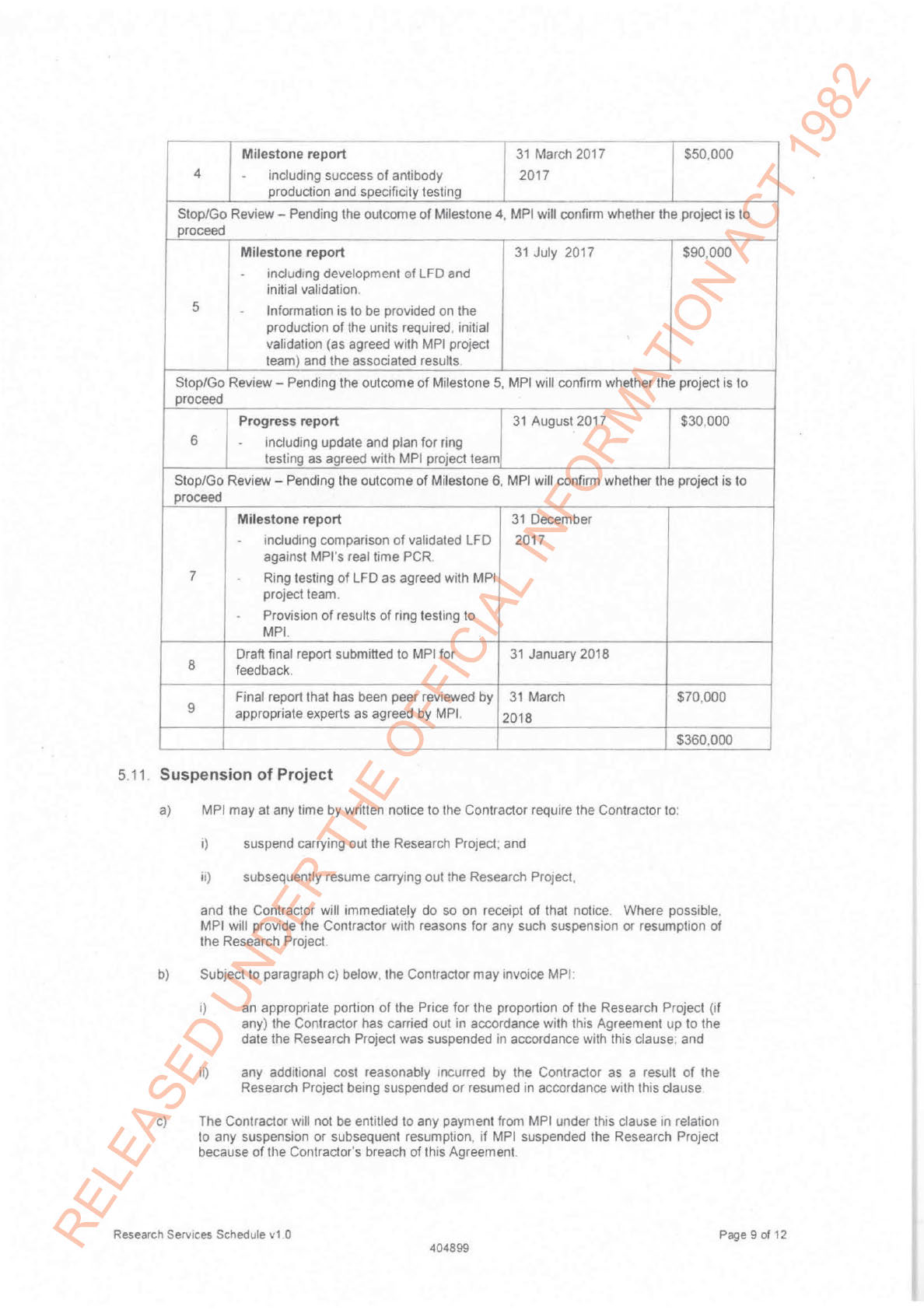

8 Appendix 2 – Requirements for Sample Processing

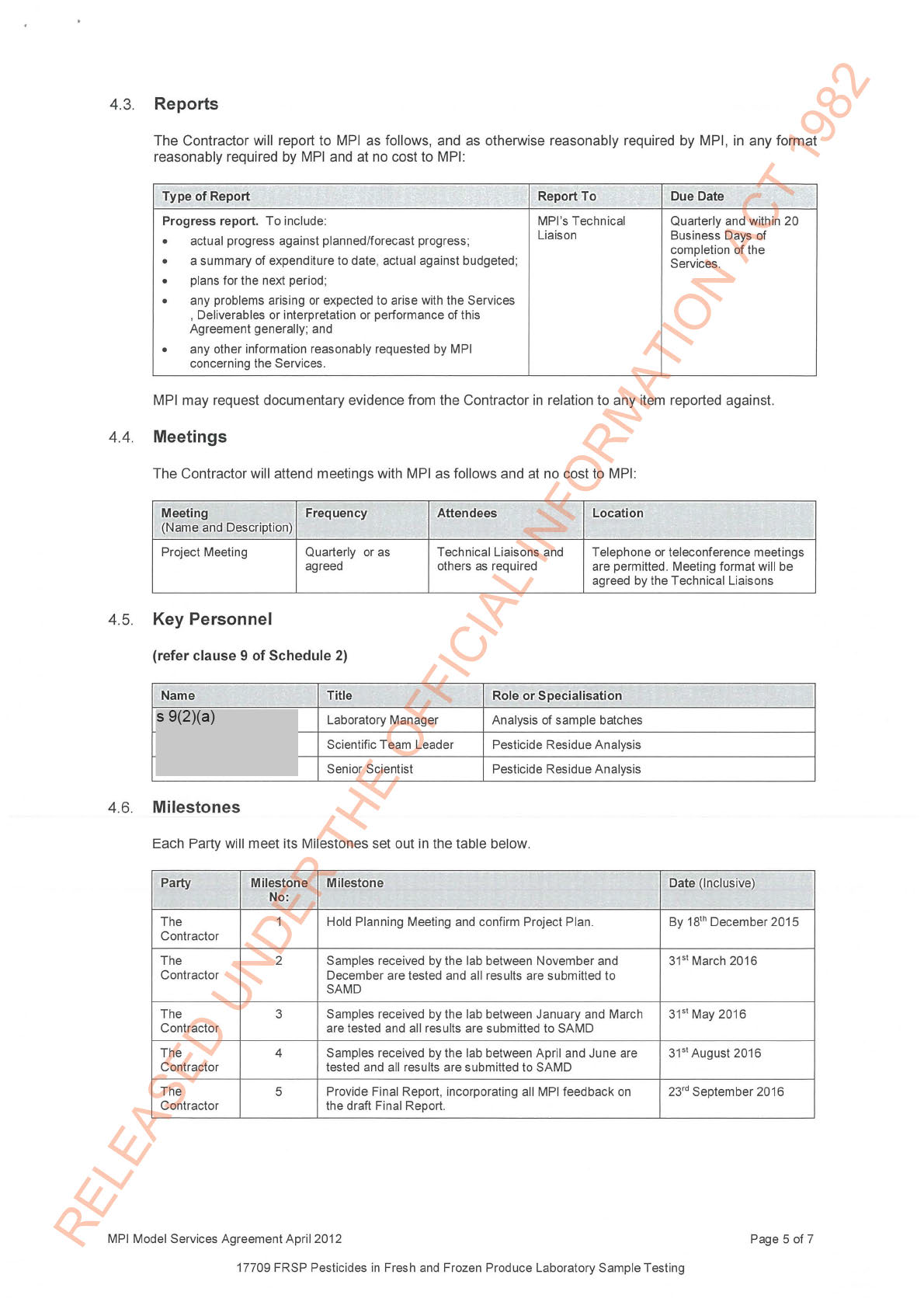

Product

Submitted

Portion of the

Sample processing required at the

sample size

commodity to which laboratory

to laboratory the MRL applies

(and which is

analysed)

Cauliflower 2 kg

Flower heads

Comminute (cut and homogenise) samples

ACT 1982

(at least 5 units)

at low temperature either frozen and/or in

the presence of “dry ice”.

Take a sufficient portion to sub-sample for

initial testing. Retain ~500g of remaining

processed material in frozen storage for re-

testing, if required. Do not allow the entire

sample to thaw when removing portions for

testing.

Kale and

2 kg

Whole commodity

Comminute (cut and homogenise) samples

silver beet

(at least 5 units) after

at low temperature either frozen and/or in

removal of obviously the presence of “dry ice”.

decomposed or

Take a sufficient portion to sub-sample for

withered leaves

initial testing. Retain ~500g of remaining

processed material in frozen storage for re-

INFORMATION

testing, if required. Do not allow the entire

sample to thaw when removing portions for

testing.

Peas

1kg

Whole commodity

Comminute (cut and homogenise) samples

at low temperature either frozen and/or in

the presence of “dry ice”.

Take a sufficient portion to sub-sample for

initial testing. Retain ~500g of remaining

processed material in frozen storage for re-

testing, if required. Do not allow the entire

sample to thaw when removing portions for

testing.

Tomatoes

1kg

Whole commodity

Comminute (cut and homogenise) samples

(at least 10

after

at low temperature either frozen and/or in

units)

removal of stems

the presence of “dry ice”.

Take a sufficient portion to sub-sample for

initial testing. Retain ~500g of remaining

processed material in frozen storage for re-

testing, if required. Do not allow the entire

sample to thaw when removing portions for

testing.

Winter

2 kg

Whole commodity

Comminute (cut and homogenise) samples

squash

(at least 5 units) after removal of

at low temperature either frozen and/or in

stems

the presence of “dry ice”.

Take a sufficient portion to sub-sample for

initial testing. Retain ~500g of remaining

processed material in frozen storage for re-

testing, if required. Do not allow the entire

sample to thaw when removing portions for

testing.

Ministry for Primary Industries

Pesticides in Fresh and Frozen Produce – Laboratory Protocol • 17

RELEASED UNDER THE OFFICIAL

Version 2 – November 2015

Wheat

1kg

Whole commodity

Comminute (cut and homogenise) samples

at low temperature either frozen and/or in

the presence of “dry ice”.

Take a sufficient portion to sub-sample for

initial testing. Retain ~500g of remaining

processed material in frozen storage for re-

testing, if required. Do not allow the entire

sample to thaw when removing portions for

ACT 1982

testing.

INFORMATION

18 • Pesticides in Fresh and Frozen Produce – Laboratory Protocol

Ministry for Primary Industries

RELEASED UNDER THE OFFICIAL