Reference Guide

Reference Guide

T3A2-rg

Type 3 MANAct

T3 001-

Information

Official

the

under

Released

Status of this document

This document is issued by the New Zealand Fire Service.

Recommendations for change: Training encourages and welcomes feedback on all our materials.

Recommendations for changes to this material should be sent to Training using the

Training Feedback Form on FireNet. You will find it under Training Information in the

Act

Training section of FireNet.

For the most up-to-date information, please refer to FireNet.

Document title: Type 3 MAN NZFS T3 001- Reference Guide

Published: December 2014

Amended: March 2015, June 2015, August 2015,

September 2015, April 2016, May 2016

© New Zealand Fire Service – Training

Information

If you wish to copy or reproduce any of the material in this document, please contact:

Team Leader, Learning and Development

Training

PO Box 2133

Wellington 6140

Official

the

under

Released

New Zealand Fire Service | Training

link to page 5 link to page 5 link to page 5 link to page 5 link to page 6 link to page 6 link to page 7 link to page 8 link to page 8 link to page 8 link to page 8 link to page 8 link to page 8 link to page 8 link to page 8 link to page 8 link to page 9 link to page 9 link to page 9 link to page 9 link to page 9 link to page 10 link to page 10 link to page 10 link to page 12 link to page 14 link to page 14 link to page 14 link to page 15 link to page 16 link to page 16 link to page 16 link to page 17 link to page 17 link to page 17 link to page 18 link to page 19 link to page 20 link to page 20 link to page 22 link to page 22 link to page 22 link to page 23 link to page 25 link to page 26 link to page 26 link to page 27

iii

Contents

Introduction 1

Purpose of this reference guide

1

Training requirements

1

Appliance identification

1

Section 1: Overview of the appliance

2

References 2

Appliance views

3

Section 2: Appliance details

4

Act

Cab and chassis

4

Body 4

Water tank

4

Main pump

4

High pressure pump

4

Monitor and base

4

Weights

4

Travel height

4

Length 5

Width 5

Tyres

5

Transmission 5

Information

Engine 5

Section 3: Appliance cab

6

Cab layout

6

Dash layout and functions

6

Siren and public address system (PA)

8

Battery and battery isolator

10

Official

10

230 volt inlet and indicator light

10

Battery charger

11

the

Section 4: General safety

12

Employer responsibilities

12

Driving safety - general

12

Section 5: Driving

13

Oil and water levels

13

Adjusting the steering wheel

13

under

Seat adjustments

14

Instrument panel

15

Running gear

16

Retarder and Brakematic systems

16

Anti-lock Braking System (ABS)

18

ASR (anti spin regulator) and ESP

(electronic stability programme) switch

18

Electronic stability programme (ESP)

19

Parking brake

21

Released

Starting the engine

22

Gear selection

22

Differential locks

23

May 2016 | Version 7

link to page 28 link to page 28 link to page 28 link to page 29 link to page 30 link to page 31 link to page 31 link to page 31 link to page 32 link to page 33 link to page 34 link to page 35 link to page 35 link to page 35 link to page 36 link to page 37 link to page 38 link to page 38 link to page 39 link to page 39 link to page 39 link to page 40

iv

Type 3 MAN T3 001- Reference Guide

Section 6: Water pumps

24

Main pump unit

24

Hosereel pump

24

Water Dragon

25

Tank refill

26

Overflows, relief valve and total pressure master system 27

Total pressure master system (TPM)

27

Pump controls and instrument panel

27

Pump engagement

28

Act

Pump disengagement

29

Hosereels 30

Section 7: Foam system

31

Foam Pro system

31

Foam tank

31

Foam Pro operation

32

Getting to work with foam

33

High / Low flow warning

34

Refilling the foam concentrate tank

34

Section 8: Equipment

35

Crossfire monitors and Safe-Tak 125 portable base

35

Information

Ladders 35

Section 9: Lighting

36

Official

the

under

Released

New Zealand Fire Service | Training

1

Introduction

Purpose of this reference guide

This reference guide is designed to prepare you, as appropriate to your

role, to drive, operate and crew the Type 3 appliance in a safe and

efficient way.

This reference guide covers the basic information required to operate

this appliance. This reference guide and the associated training do not

replace specific driver, pump operator, and firefighter training.

Act

Training requirements

Before the vehicle can be operational at your station, all crew members

must:

• self-study using this reference guide

• familiarise themselves with the vehicle, as appropriate to their role

Information

• complete the Type 3 MAN NZFS T3 001 Familiarisation Checklist.

Appliance identification

Each Type 3 MAN appliance has a New Zealand Fire Service

identification number. This number is part of a sequential list (T3 001,

Official

T3 002, T3 003, etc.). It enables you to ensure this is the correct

reference guide for your specific vehicle. The identification number is

on the plate inside the driver’s door, next to the Fraser Fire and Rescue

ID.

the

under

Released

NZFS Identification number

May 2016 | Version 7

2

Section 1: Overview of the appliance

References

Policies

Policy and Operational Instructions that apply:

The driving of New Zealand Fire Service (NZFS) appliances is covered

by policy FL1-1 Driving Operational Vehicles. FL1-1 should be

reviewed by all drivers and officers as part of your training.

Act

FL1-1 is available on FireNet.

FL1-1 provides instructions for driving NZFS operational vehicles, and

includes information on safety requirements.

Manufacturers’ manuals

Type 3 Appliance manufacturer’s manual

This manual contains the manufacturer’s specific information regarding

operator use and servicing details for the major components of the

appliance. Each appliance is issued with a manual on entering service; Information

Fraser Fire and Rescue produce this manual.

Fraser Fire and Rescue operational and maintenance

manual

This manual contains general information:

Official

• operating procedure

• general information

the

• routine checks.

MAN Owner’s Manual

This manual contains information specific to the factory cab, chassis

and driveline components of the appliance.

under

It tells you what you need to know about the vehicle to be able to drive

it without risking damage to the vehicle or injury to yourself.

Darley LSP 1000 And HD 100 Operational and

Maintenance Manual

This manual contains information specific to the pump:

Released

• operating procedure

• preventative maintenance

• trouble shooting

• corrective maintenance.

New Zealand Fire Service | Training

3

Section 1: Overview of the appliance

Appliance views

Full details of the major components can be found in the respective sections of this reference manual.

Act

Off-side view

Information

Official

the

Near-side view

under

Released

May 2016 | Version 7

4

Section 2: Appliance details

Cab and chassis

MAN TGM 290HP 4 x 2 BL Crew Cab fitted with Fraser BA seats.

• 4 x 2

• single steer front axle with conventional tyres

• air bag rear suspension height switch on the dash

Act

• cruise control

• electronic speed limiter.

• electronic stability programme (ESP)

• ABS braking.

Body

Information

The body is constructed from marine-grade aluminium and fitted with

Fraser Fire and Rescue doors.

The maximum allowable weight for each locker is marked on the locker

door catch.

Official

Water tank

1450 litre capacity

the

Main pump

Darley LSP1000 Midship PTO driven

under

High pressure pump

Darley HD100 PTO driven

Monitor and base

TFT Crossfire with Safe-Tak 1250 Portable base

Released

Weights

Operational weight: 13 000 kg

Travel height

3.2 metres

New Zealand Fire Service | Training

5

Section 2: Appliance details

Length

8.5 metres

Width

2.5 metres

Act

Tyres

Front

Size

- Continental 305/70R 19.5

Pressure - 770 kPa

Rear

Size

- Continental 305/70R 19.5

Information

Pressure - 570 kPa

Transmission

ZF 5 HP automatic 5 speed transmission with an integrated retarder

Official

Engine

MAN 6 cylinder inline, turbo charged, Intercooler, 290 HP at 2300 rpm

the

under

Released

May 2016 | Version 7

6

Section 3: Appliance cab

Cab layout

The following diagrams show only those controls/switches and

warning lights pertinent to the operation of the appliance. Full details

NOTE

of factory Man cab layout can be found in the Man Operator’s Manual.

Do not drill holes into the

Dash layout and functions

cab or modify in any way.Act

Controls – left of steering column

1

2

Information

3

Official

the

6

5

4

1. Climate controls

2. Wipers and window washers

under

3. Inhibit override

4. Anti spin regulator

5. Diff lock

6. Rear suspension lowering

Released

New Zealand Fire Service | Training

7

Section 3: Appliance cab

Controls – right of steering column

1

2

3

Act

4

5

1. Adjust mirror

8

7

6

Information

2. Select the mirror on the left or right of the vehicle

3. Selects mirror to adjust

4. Switch mirror heater on and off

Official

5. Check lamp comes on when mirror heater is activated

6. Central locking

the

7. Window raise/lower switch

8. Move the main mirror out briefly

under

1

2

3

4

Released

1. Fog lamp

2. Hazard light

3. Retarder control stalk

4. Brakemmatic, cruise control and road speed limiter stalk

May 2016 | Version 7

8

Type 3 MAN T3 001- Reference Guide

Act

Grille release.

This catch unlocks the grille. A second

catch at the bottom centre of the grille

needs to be released when you lift

the grille (same process as most car

bonnets).

Information

Siren and public address system

(PA)

Official

The siren is operated from the cab control console. To operate the

siren, the beacons must be on.

the

under

Emergency response

Beacons

Siren

air horn

Released

New Zealand Fire Service | Training

9

Section 3: Appliance cab

The siren tones are operated from the siren control hand piece which is

located on the officer’s side of the storage compartment.

Siren control

Push to

Siren

hand piece

talk (PTT)

Microphone

tones

Act

Information

Official

To use the PA, the beacons must be switched on. Note: the siren

does not need to be on. If the siren is in use, the PA can also be used.

In this case, the PA will override the siren while you are talking. The

siren will resume once you have finished talking.

the

Press the PTT button to activate the public address function.

The PA volume is displayed any time the PTT button is depressed, as

shown below.

under

Level 1

Level 2

Level 3

Level 5

(min)

(max)

Released

+

Increase PA volume

+

Decrease PA volume

May 2016 | Version 7

10

Type 3 MAN T3 001- Reference Guide

Battery and battery isolator

Act

Batteries

Information

Battery isolation switch

230 volt inlet and indicator light

Official

the

under

230 volt inlet

Released

New Zealand Fire Service | Training

11

Section 3: Appliance cab

Battery charger

The battery charger is mounted on the rear wall behind the number 4

seat.

Act

Portable pump

battery charger

indicator light

Information

Official

If the indicator light below the 230 volt inlet is not illuminated, it

indicates no power to the appliance charger. Check the circuit breaker

beside the charger and in the engine house.the

The charger is fully automatic. To switch it on, press the power switch

and hold for three seconds. The power switch will illuminate green.

Once switched on, the charger automatically resumes operation when

NOTE

reconnected to the 230 volt supply.

under

On the left hand side of the steering wheel is a 230-volt inhibitor

When the vehicle is plugged

override. The vehicle cannot be started while the vehicle is connected

in correctly, the green light

to the 230-volt supply. In the unlikely event of relay failure or the

below the cab inlet plug will

vehicle needing to be started with the 230 volt connected, the red

light up after 15 seconds.

knob on the left hand side of the steering wheel labelled ‘inhibit

override’ can be pushed, allowing the vehicle to be started. Under

normal conditions this is not required.

Released

May 2016 | Version 7

12

Section 4: General safety

Employer responsibilities

Employers must ensure:

• the appliance is operated by competent operators and is used in

accordance with the operating instructions

• appropriate documentation and records are maintained

Act

• the appliance is inspected regularly, repaired and maintained by

those competent to carry out such work and that periodic testing is

carried out.

Driving safety - general

Overview

The following notes are general safety notes pertaining to this

Information

appliance they are not intended to fulfil the requirements of the

Emergency Response Driver training for this appliance.

Pre-driving checks

NOTE

Before starting road transportation:

Official

• complete the standard Career appliance daily checklist (FL7 FML)

The Career appliance

• check:

daily checklist FL7 FML is

available on FireNet.

the

– all equipment in lockers is stowed correctly

– all lockers are closed

– the monitor and light masts are housed.

under

Vehicle braking warning

Due to the weight of this vehicle, drivers must take care when braking

and ensure the vehicle is driven to the road and weather conditions.

Released

New Zealand Fire Service | Training

13

Section 5: Driving

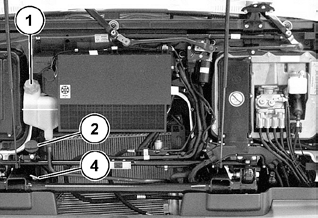

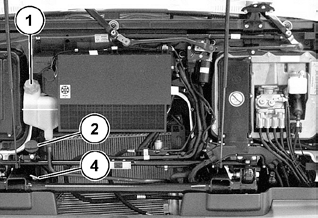

Oil and water levels

Act

3

Information

1. Filler neck for coolant

2. Filler neck for engine oil

3. Dipstick for engine oil

Official

Adjusting the steering wheel

the

1. Press and hold the push button

on the driver’s seat console

with your heel.

2. Set the rake and reach of the

steering wheel.

under

3. Release pushbutton again. The

steering wheel locks into place.

Released

Steering wheel

adjuster

May 2016 | Version 7

14

Type 3 MAN T3 001- Reference Guide

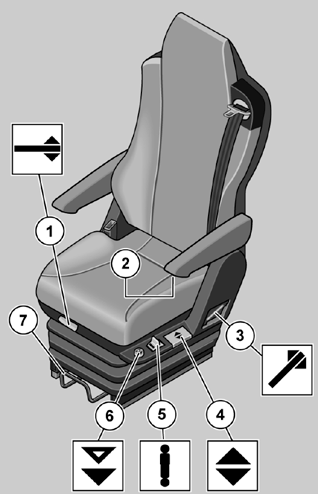

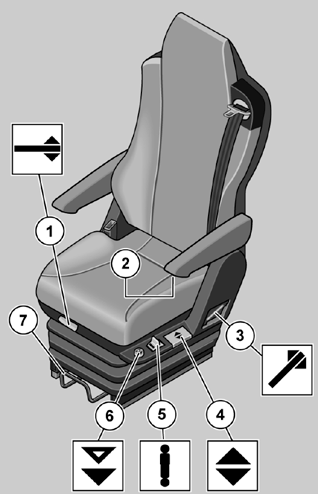

Seat adjustments

Act

Information

Official

the

under

1. Seat surface angle

Released

2. Arm rests

3. Backrest angle

4. Seat surface height

5. Vertical damper adjustment

6. Quick lower - for getting in and out

7. Whole seat backwards and forwards

New Zealand Fire Service | Training

15

Section 5: Driving

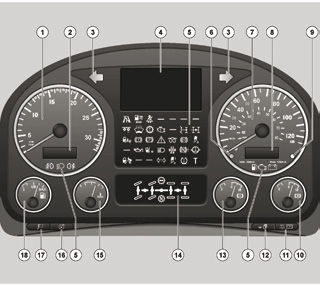

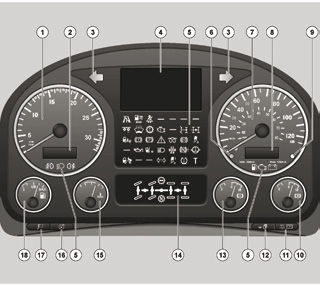

Instrument panel

Act

Information

Official

1. Rev counter

NOTE

2. Outside temperature

– black ice warning

the

– total mileage

For more information on

the instrument panel, refer

3. Turn indicators, tractor

to pages 40-41 of the Man

Operator’s Manual.

4. Display

under

5. Check lamps

6. Sensor for automatically adjusting brightness of the instrument

lighting and the EU monitoring device display

7. Speedometer

8. Time

trip counter

Released

speed

9. Warning speed

10. Reservoir pressure in brake circuit

11. Information messages on display

trip odometer or speed

vehicle menu

May 2016 | Version 7

16

Type 3 MAN T3 001- Reference Guide

12. Information messages on display

vehicle menu

NOTE

13. Reservoir pressure in brake circuit

14. Differential locks

Do not accelerate and brake

at the same time the exhaust

15. Coolant temperature

brake is engaged. Doing so

could cause damage by over

Act

16. Instrument lighting

pressurising the engine.

17. Select language

18. Fuel level

Running gear

Lowering rear suspension

Information

Press to lower the rear of the

body from drive height to a kneel

position. This will lower the rear

of the appliance by 150 mm to

assist with the removal of the

ladder from the gantry.

Official

Press again to return the rear of

the body to drive height.

the

If the rear of the appliance is

in the kneel position when the

appliance is driven at 5 km per

hour the appliance automatically

returns to the drive height. under

Retarder and Brakematic systems

The MAN appliance has two braking systems: foot brakes, and a

Released

transmission retarder.

These automatically combine when the Brakematic function is

activated when travelling down hill.

The appliance computer will automatically decide which system, or

a combination of both systems, to use to hold the appliance at the

selected speed. The Brakematic system is not cruise control.

New Zealand Fire Service | Training

17

Section 5: Driving

Retarder control stalk

MAX/OFF button

Act

Cruise control stalk

Information

Retarder and Brakematic controls

Retarder

The retarder is a hydraulic brake driven by the transmission output

Official

shaft. It is used to supplement the foot-brake system and also to

NOTE

control downhill speed. There are three levels of braking, from low

braking (level 1) to maximum braking (level 3).

the

The retarder is fully integrated with the brake pedal. The driver does

There is no need to turn

not need to use the retarder stalk on the steering column to engage the

the retarder off for wet

retarder.

surfaces. The ESP system

has overall control over the

The first 25% of the brake pedal travel is mainly retarder, but the

braking system including the

service brake will come on initially as the retarder takes a second or

retarder and will take over in

under

two to build up pressure. Once the retarder is up to pressure it takes

any situation it deems to be

over the braking. As the brake pedal is depressed towards 25% of it’s

unsafe.

travel the service brake starts to work and increases smoothly as more

foot brake is applied.

Under heavy braking both the service brakes and 100% retarder are

working together. The retarder symbol will appear on the instrument

panel but there will not be a number with it.

Released

The stalk also operates the retarder, it has 3 positions. Position 1

selects 40% retarder, position 2 selects 70% retarder and position

3 selects 100% retarder. The button at the end of the stalk sets the

retarder to 100%.

You might find the stalk to be a more suitable control for cruising down

long descents.

May 2016 | Version 7

18

Type 3 MAN T3 001- Reference Guide

–

MAN Brakematic

The Brakematic system is primarily for downhill use. When the system

is engaged, it will keep the vehicle travelling at the speed selected by

NOTE

the driver by automatically using the retarder and foot brakes.

Act

To engage:

When adjusting the speed

setting, the Brakematic will

momentarily disengage then

1. Set the required downhill speed by applying the foot brake for a

reengage at the new speed.

minimum of three seconds.

2. Switch on the MAN Brakematic system using the rocker switch on

the Cruise Control stalk (MEM/OFF).

The MAN Brakematic is now engaged and will maintain the vehicle at

the current speed.

Information

Depressing the brake pedal will temporarily override the system.

Releasing the brake pedal will reengage the Brakematic system at the

new speed.

To disengage:

Official

Depress the accelerator.

Anti-lock Braking System (ABS)

the

The ABS compares the speed of each wheel and adapts braking

power accordingly so that no wheels lock up.

The advantages of ABS are:under

• shortest possible stopping distances without loss of steering and

directional stability

• higher degree of control on slippery surfaces

• reduced tyre wear.

SAFETY NOTE

ASR (anti spin regulator) and ESP

Released

(electronic stability programme)

When the ASR/ESP is

deactivated the vehicle is

switch

less safe, as there is no

automatic intervention by the

brake system.

Only deactivate this system if off road. On other road surfaces, the

ASR/ESP system must be activated.

Drive to the conditions at all

times.

New Zealand Fire Service | Training

19

Section 5: Driving

Electronic stability programme (ESP)

ESP is a safety system that assists the driver in critical situations, for

example:

• skidding (over steer and under steer)

• risk of overturning

Act

by

• improving the ability to control and steer the vehicle

• reducing the risk of overturning.

The ESP system includes sensors that measure the stability of the

appliance.

The ESP system is connected to the braking and engine management

systems and possesses two vehicle-stabilising sub-functions. One of Information

these is mainly active when adhesion values are low to medium, and

helps to counteract over steer and under steer. The other sub-function

mainly takes effect when adhesion is moderate to high, and reduces

the risk of overturning. The two sub-functions are linked via an

interface and operate together. The ESP check lamp on the instrument

panel screen flashes yellow when ESP is active.

Official

ESP directional stabilising

ESP keeps the vehicle stable over surfaces with low or moderate

the

adhesion, provided that the dynamic limits are not exceeded. It

counteracts the tendency to over or under steer in certain situations.

In these situations the ESP will apply the brakes to individual wheels

to correct the behaviour of the vehicle. The ABS system will ensure

wheel lock up is prevented. under

ESP to reduce the risk of overturning

This function is intended to prevent the vehicle from overturning in

certain situations (subject to being driven within the dynamic limits

imposed by the laws of physics). This function is mainly needed at

moderate to high levels of road grip.

ESP performs this function in two stages:

Released

1. The first stage reduces the vehicle’s road speed until lateral

acceleration is below the critical level at which overturning could

occur.

May 2016 | Version 7

20

Type 3 MAN T3 001- Reference Guide

2. In the second stage, any wheel which leaves the road surface on

the vehicle is detected. If a vehicle wheel lifts away from the road

surface, the second ESP stage applies all the vehicle’s brakes. The

ABS system will ensure wheel lock up is prevented.

Act

Information

Official

the

under

Released

New Zealand Fire Service | Training

21

Section 5: Driving

Parking brake

To apply the park brake, push the lever backwards until it engages.

Act

Park brake lever

Information

Air tank drain

The air tank drain is on the offside, below the A locker.

Official

the

under

Released

Air tank drain

May 2016 | Version 7

22

Type 3 MAN T3 001- Reference Guide

Starting the engine

To start:

• depress the brake pedal.

• put the vehicle in neutral

• turn the ignition key until the glow-plug symbol shows

Act

• when “START ENGINE” is displayed, turn the ignition key fully.

If the engine doesn’t start, check the battery master switch is on.

Gear selection

Automatic transmission

Information

Official

Modes

the

The following ZF 5 HP automatic transmission modes can be selected

with the mode switch:

• ‘D’. Drive forwards, unrestricted mode

Start off in 1st gear, automatic upshifts up to 5th gear.

under

• ‘D1’, ‘D2’, ‘D3’. Drive forwards, restricted mode

– ‘D3’. Start off in 1st gear, automatic upshifts up to 3rd gear

– ‘D2’. Start off in 1st gear, automatic upshifts to 2nd gear.

– ‘D1’. Start off in 1st gear – no upshifts

Released

– ‘R’. Drive reverse.

New Zealand Fire Service | Training

23

Section 5: Driving

Changing modes

When changing modes from drive to reverse or back:

NOTE

1. Ensure the vehicle is stationary.

2. Place your foot hard on the brake pedal.

Important:

3. Move the selector from drive to neutral, pause briefly, move to

Do not change from drive Act

reverse.

straight across to reverse.

The transmission will not

The process is the same for going from reverse to drive.

engage the selected mode.

Differential locks

To clear, place the selector

in neutral and wait five

seconds and re-select mode.

The appliance is fitted with a differential lock. Only engage the

differential lock when traction is lost and the vehicle is travelling in a

straight line at a speed of less than 7 km/hr.

Information

As soon as the appliance returns to hard standing, the diff lock must

be disengaged. Damage can occur to the drive axles if the differential

lock is left activated and driven on a normal road surface.

Official

the

under

Released

May 2016 | Version 7

24

Section 6: Water pumps

Main pump unit

The Darley pump unit is mounted on the pump frame and is PTO

driven.

SAFETY NOTE

There are two important output ratings, one for normal firefighting use

When using the water pump,

with low pressure deliveries, and the other relevant to acting as a base

always use Class 2 hearing

pump for aerial appliances.

protection.

Act

1. 3840 litres per minute @ 1050 kPa

2. 3600 litres per minute @1500 kPa - through delivery outlets to an

aerial

Hosereel pump

The Darley pump unit obtains its power from the vehicle’s PTO. The

hose reel pump is mounted on the nearside lower section of the pump

frame. This unit is controlled from the main pump panel by the same

Information

electronic hand throttle that controls the main pump.

Official

the

Hosereel rewind

under

Released

New Zealand Fire Service | Training

25

Section 6: Water pumps

The hose reel pump is fed by the main pump. Both must be running

when using the hose reels.

When using the hose reels from the tank, it is recommended you prime

the pump after opening the tank-to-pump valve to evacuate the air

from inside the pump.

The hosereel system is designed to provide 440 litres per minute @

2400 kPa. At this setting the main pump pressure will be 1050 kPa.

Act

Water Dragon

To operate the water dragon set the hose reel pump pressure to 2400

kPpa. This will provide 1500 l/m @ 1050 kPa from the main pump to

deliveries.

Information

Official

the

under

Released

May 2016 | Version 7

26

Type 3 MAN T3 001- Reference Guide

Offside pump panel

Act

Information

Hosereel rewind

Official

the

under

Tank refill Tank refill inlet

Released

The tank refill inlet bypasses the pump and feeds directly into the tank

for manually filling the tank. The main purpose of this feature is to allow

the tank to be refilled while draughting by connecting a delivery outlet

to the direct tank fill with standard hose.

There is no tank refilling capability on the roof.

New Zealand Fire Service | Training

27

Section 6: Water pumps

Overflows, relief valve and total

pressure master system

The overflow from the water tank is piped to ground and is behind the

rear axle. The cooling lines are piped to the water tank, so will dump

water to ground through the water tank overflow when the water tank

is full.

Act

The suction relief valves (one each side of the vehicle) are preset to

1150 kPa. They are designed to protect the supply line into the pump.

The suction relief valves are fitted between the collector head and the

intake valve. In the event of high intake pressure, the relief valve opens

and the excess water dumps to ground below the pump panel on each

side.

The high pressure pump has a preset (kunkle) pressure relief valve,

which has been set to 4200 kPa. When this valve opens; the water

goes to ground under the nearside pump step.

Information

The main pump is fitted with a Total Pressure Master (TPM) discharge

relief valve. To maintain the desired discharge pressure, the TPM

will relieve to the suction side of the water pump. If the desired

discharge pressure is still not achieved, the TPM will dump to ground

underneath the pump panel.

Total pressure master system (TPM)

Official

To set the TPM:

the

1. Open the throttle until the desired pressure is achieved.

2. Turn the wheel slowly anti-clockwise until the relief valve opens

(amber light comes on).

3. Turn the wheel slowly clockwise until the amber light goes off.

under

Amber light functions:

– steady – venting to pump inlet

– flashing – venting to atmosphere.

Shutting down the TPM:

Released

1. Reduce engine RPM to idle.

2. Set TPM to normal operating pressure.

Pump controls and instrument panel

The pump panels are engraved and colour coded to assist in

May 2016 | Version 7

28

Type 3 MAN T3 001- Reference Guide

component identification and relativity to each other.

The colour coding system is as follows:

• blue – main pressure

• green – pump suction

• pink – high pressure

Act

• yellow – foam.

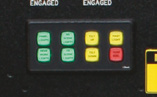

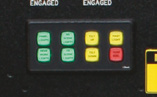

Pump engagement

There are two P.T.O.s. One drives the main pump, the other drives the

hose reel pump.

The pumps must be engaged in the following sequence:

• Main pump first, followed by the hose reel pump.

Information

• Reverse to disengage.

The hose reel pump will not work if the main pump is not engaged.

Engaging the transmission, or releasing the park brake will result in the

pumps automatically disengaging. If this happens the pumps must be

Official

re-engaged using the pump switches.

Main pump

the

To engage the main pump:

1. Stop the vehicle.

2. Apply the park brake. under

3. Shift the transmission into

Released

New Zealand Fire Service | Training

29

Section 6: Water pumps

neutral.

NOTE

4. Ensure engine is at idle.

5. Hold the main pump switch until Light On shows.

• The engine revs must be

below 900 rpm before the

6. Main pump is now ready.

PTO will engage.

• Keep the transmission in

Act

Hosereel pump

neutral at all times while

pumping.

To engage the hose reel pump:

1. Stop the vehicle.

2. Apply the parking brake.

NOTE

3. Shift the transmission into neutral.

4. Engage the main pump.

Disengaging the parking

Information

brake will disengage the

5. Hold the hose reel pump switch until the light comes on.

pump.

Pump disengagement

Main pump

Official

To disengage the main pump:

the

1. Ensure the engine is at idle.

2. Hold main pump switch until Light Off shows.

3. The main pump is now disengaged.

under

Hosereel pump

To disengage the hosereel pump:

1. Ensure the engine is at idle.

2. Hold hosereel pump switch until Light Off shows.

Released

3. The hosereel pump is now disengaged.

May 2016 | Version 7

30

Type 3 MAN T3 001- Reference Guide

Hosereels

Two Fraser Fire and Rescue hose reels are mounted on top of the

pump module. Each is fitted with 92 metres of Boston booster hose

and TFT ULTIMATIC 125, 500 kPa model BL-BGH branches, and each

hose reel is fitted with power and manual rewind systems. Circuit

Breakers are fitted to the nearside pump panel. A water shutoff valve

is positioned on the main pump panel.

Act

A friction brake is fitted to each hose reel. In the event of a power

failure, the hose can be rewound manually. To rewind the hose, insert

the supplied handle through the front of the hose reel bollard onto the

bevel gear shaft. Then push to engage the manual rewind gear with

the beveled gear on the drum.

Information

Official

the

under

Released

New Zealand Fire Service | Training

31

Section 7: Foam system

Foam Pro system

The foam system is a Foam Pro 2002 direct injection with a 53 litre

plastic tank and on-board foam refill pump.

Foam is available from both the nearside delivery outlets, both hose

reels, and the deck monitor.

The waterway is configured to deliver water only, from both offside

Act

delivery outlets.

The Foam Pro system is an electrically driven, flow-based

proportioning system that measures water flow and injects a

proportional amount of foam concentrate into the discharge side of the

pumps.

The foam system is designed for Class A foam only.

The foam proportioning and multi-flow gauges are mounted to the right

of the Foam Injector Selection switch.

Information

Foam tank

The foam tank is plastic and has a capacity of 53 litres.

The tank is located at the bottom of the offside pump panel. For

Official

manual filling of the tank, slide it out of the locker and remove the tank

lid.

the

Refilling

There is a self-priming, flexible impeller pump with a flow rate of

approximately 20 l/min, mounted behind the nearside pump panel.

This is used to transfer foam concentrate to the foam tank.

under

Foam is taken up through a pick-up tube connected at the nearside

pump panel when required.

A sensor is fitted to the top of the tank to stop the foam concentrate

pump when the level has reached a maximum.

System priming

Released

Upon receiving your new Type 3 appliance, the foam concentrate

system will need to be charged. To do this:

1. Fill the foam tank with Class A foam.

2. Turn the foam system on by pressing the red FOAM button and set

it to normal pressure.

3. Set the foam percentage to 10% by pressing the SELECT button

until the indicator is beneath “ % ”, then use the UP arrow to

increase the rate to 10%.

May 2016 | Version 7

32

Type 3 MAN T3 001- Reference Guide

4. Open a foam capable low-pressure delivery outlet and run the main

pump up to approx 150 L/min until foam is present.

5. Switch the foam system to high pressure and run a hosereel

at something close to its normal maximum output until foam is

present.

6. Close down and flush the water pump waterway as usual.

Act

7. Set the foam pump proportioner back to the normal operating

percentage. (Note: the lower the main water pump pressure the

faster the prime. Therefore do not fit a nozzle to the delivery outlet

being used).

Contents level

The foam concentrate contents gauge is mounted on the left side of

the pump panel next to the Foam Injector Selection switch.

Information

When the foam level drops to 1/8, the LED lights on the contents

gauge will begin to flash to alert the pump operator.

Foam Pro operation

High or normal pressure

Official For detailed instruction on

The Foam Pro system will inject foam into either the hosereel pump, or

the operation of the Foam

the main pump, but not both at once.

the

Pro system, refer to the

Foam Pro and Darley Pump

Making the selection between high or low pressure tells the foam

Operation manuals.

proportioning system which flow meter to monitor and which injector

to send foam concentrate to.

under

Flow measuring

The Multi-flow system performs two functions:

1. It measures water flow. This is necessary for the proportioning

system to deliver the selected percentage of foam concentrate into

the water stream

2. Displays flow rates.

Released

New Zealand Fire Service | Training

33

Section 7: Foam system

The pump operator can select from the following display options on

the Multiflow panel:

• the combined water flow through the hose reels

• the flow through the foam capable low pressure delivery.

The flow through the low pressure deliveries is measured for the foam-

capable low pressure delivery only.

Act

Foam proportioning

The foam proportioning controls include the following:

NOTE

• a button to start and stop the injection of foam concentrate (change

from delivering plain water to delivering foam solution)

Always ensure the monitor

• selection of what is displayed

is down before driving the

appliance.

Information

• adjustment of the percentage of foam concentrate injected into the

water stream.

Display options

The foam proportioner display can show:

Official

• the flow rate through the selected (high or low pressure) outlets

• the total volume of water pumped

the

• the percentage of foam concentrate being injected

• the total volume of foam concentrate that has been used.

NOTE

Remember to reset the total water and total foam displays to zero

under

before pumping. The displays are reset by pressing the and

buttons on the foam proportioner at the same time when the

appropriate reading is displayed.

After every use, ensure the

pump is flushed until no

foam residue is visible.

Getting to work with foam

Delivering foam

Released

To deliver foam solution:

NOTE

1. Start delivering water as usual.

The maximum working

2. Set the injection selector to either high or low (normal) pressure

pressure the foam system

discharge as required.

can inject foam is at 2700

kPa.

3. Check and adjust the foam percentage as required.

May 2016 | Version 7

34

Type 3 MAN T3 001- Reference Guide

4. Start the injection of foam concentrate by pressing the on/off button

on the foam proportioner control panel.

5. Monitor the contents level of the foam tank.

High / Low flow warning

Act

If the foam concentrate pump cannot supply the correct proportion of

foam it will display a warning on the foam control display.

“Lo.Flo” means there is so little water flowing that the foam system

cannot accurately supply such a small quantity of foam concentrate.

“Hi.Flo” means that there is so much water flowing that the foam pump

cannot supply enough foam concentrate to maintain the selected

concentration.

Refilling the foam concentrate tank Information

The foam tank is filled via an on-board foam refill pump as follows:

1. Connect the foam pickup tube (supplied) to the Dry Break fitting on

NOTE

the pump panel.

2. Place the other end into the foam container.

The refill pump will

Official automatically switch off

3. Press the foam pick-up pump button in until the foam starts to flow.

when either the foam tank

Hold button in to continue pump operation until foam tank is full.

is full, or the foam transfer

(Foam tank capacity = 53 litres, foam is normally carried in 20 litre

pump is dry for more than 30

the

drums).

seconds.

4. Remove the foam pickup tube.

5. Flush the pick-up and flush away any foam spilt during refilling.

under

Released

New Zealand Fire Service | Training

35

Section 8: Equipment

Crossfire monitors and Safe-Tak 125

portable base

The monitor unit mounted in the pump frame, is a TFT 18” Extend-a-

gun with a crossfire monitor, and is fitted with a Master Stream 150-

1250 nozzle. Operation of the monitor is from the body roof platform

position. The waterway open/close switch is mounted on the monitor

support tube. It will not operate until the monitor is fully extended.

Act

There is a warning light in the cab, which comes on when the monitor

is extended.

The monitor can be ground mounted, by using the Safe-Tak 1250

portable base. To ground mount:

1. Position the monitor over the base.

2. Slide it onto the portable base until the pawls engage.

Ladders

Information

The appliance is fitted with three ladders:

• a 10.5 m rescue ladder (a 464 Rescue Ladder can be fitted)

• two access ladders.

Official

Rescue ladder is mounted on a fixed beam gantry on the top deck of

the appliance. Two access ladders are stowed in the rear locker.

To remove the rescue ladder, lift the manual release arm only when the

the

crew is positioned at the foot of the ladder. The ladder will slide back

due to gravity.

When housing the rescue ladder, ensure the head of the ladder is kept

up off the gantry, and the weight of the ladder is taken by the rollers at

the base of the gantry. Once the ladder gets beyond the tipping point

under

and the head naturally settles on the centre guide on the gantry, finish

housing the ladder.

Once housed, position the locking fork on the 2nd last ladder rounds.

Secure the manual release arm.

NOTE

The suspension may be lowered to assist removing and housing the

ladder.

The ladder must be held

before releasing, as it will

Released

slide back or forward due to

gravity.

Ladder locking pin and

manual release arm

May 2016 | Version 7

36

Section 9: Lighting

Switches

The following lights are switched on at the pump panel:

• scene lights

• pump panel light

• mast light.

Act

Note the work light master switch, located on the control head in the

cab, must be switched on.

Body roof lights are switched on and off from the work light master

switch.

Locker lights

All locker lights will come on when a locker door is opened, provided

the vehicle park lights are on.

Information

Letterbox lighting

Letter box lights are located on the roof beside the front beacons.

They are switched on from the control head in the cab.

Official

the

under

Released

New Zealand Fire Service | Training

37

Notes

Act

Information

Official

the

under

Released

May 2016 | Version 7

Act

Information

Official

the

under

Released

Document Outline