STRICTLY CONFIDENTIAL

STRICTLY CONFIDENTIAL

ASBESTOS INVESTIGATION

Summary of Findings Report

16 April 2018

To:

)

Plant and Food Research

Mt Albert Road

Mt Albert

Auckland

From:

Thompson & Clark Investigations Ltd

Ph:

@tcil.co.nz

link to page 3 link to page 4 link to page 4 link to page 6 link to page 8 link to page 8 link to page 9 link to page 10 link to page 11 link to page 11 link to page 11 link to page 12 link to page 13 link to page 13 link to page 14 link to page 14 link to page 15 link to page 15 link to page 18 link to page 19

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Table of Contents

EXECUTIVE SUMMARY .........................................................................................................................3

SITUATION ..............................................................................................................................................4

2.1.

Background ......................................................................................................................................4

2.2.

Incident .............................................................................................................................................6

INVESTIGATION .....................................................................................................................................8

3.1.

Areas of Focus .................................................................................................................................8

3.2.

Legislation ........................................................................................................................................9

3.3.

Risk ............................................................................................................................................... 10

3.4.

Timeline ......................................................................................................................................... 11

FINDINGS ............................................................................................................................................. 11

4.1.

Alternative Options ........................................................................................................................ 11

4.2.

Removal Methodology .................................................................................................................. 12

4.3.

Role Definition ............................................................................................................................... 13

4.4.

Intermittent engagement of expert ................................................................................................ 13

4.5.

Progressive Scope of Work........................................................................................................... 14

4.6.

PFR Response .............................................................................................................................. 14

4.7.

Site specific risk assessment ........................................................................................................ 15

RECOMMENDATIONS ......................................................................................................................... 15

CONCLUSION ...................................................................................................................................... 18

APPENDICES ....................................................................................................................................... 19

2

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

EXECUTIVE SUMMARY

On 13 February 2018, Thompson & Clark Investigations (T&C) commenced an investigation on

behalf of Plant and Food Research (PFR) into the recent discovery of asbestos containing material

located in the Plant room of the Annex building, 120 Mt Albert Road, Sandringham, Auckland. The

enquiry was initiated at the request of Worksafe New Zealand.

Refurbishment of the PFR Hamilton building and Annex Plant room commenced in 2015 with the

removal of Asbestos Containing Material (ACM) from the Plant room, followed by the six floors and

Risers within the principal building.

were appointed as the contractors to undertake the refurbishment process,

assigning

to undertake the removal of ACM and subsequent disposal of these

materials.

No evidence has become apparent to suggest that any party involved in the asbestos removal

process and subsequent clearance has been negligent, however through a lack of cohesion

between and within operating entities the issues as described below have arisen. This has been

further exacerbated by an apparent regression in communication and relationships between these

entities.

With significant legislative changes pertaining to asbestos removal, a requirement for an increase

in PCBU (Person Conducting a Business or Undertaking) engagement across all contractor

responsibilities will be required going forward into the new legislative environment and forms part

of the recommendations in this report.

Recommendations arising from this investigation have been identified from an external perspective.

Included is the continued engagement of an independent asbestos expert throughout the

remainder of the refurbishment project and the establishment of an overall governance document

specific to the removal of asbestos. Parallel to this are the obligations of the ‘Officer’, or CEO to

ensure direct involvement in this risk is mitigated through robust processes and contractor

awareness. Further, a lack of cohesion and communication is apparent between the various entities

3

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

involved and a result of the exclusion of an overall governance process specific to the removal of

asbestos.

Despite this disconnect in processes, the risk to PFR staff and contractors is considered, and has

been assessed, to be very low.

This report discusses findings from the investigation undertaken and makes recommendations

based on information discovered during the course of this inquiry. External contractors were

requested (by TCIL & PFR) to participate in the investigative process and despite best efforts

neither party responded during the course of the 8-week enquiry to requests for interviews or written

questions provided by TCIL. It is not anticipated, however, that their input would greatly influence

the outcomes of this report.

SITUATION

2.1. Background

Completed in 1972, the Plant and Food Research Hamilton building consists of a six-level design,

with a level seven plant/motor room. Immediately adjacent to the principal building is a two-level

Annex building containing a Plant room beneath. A seismic concrete wall separates the two

structures.

As is common with construction of this era, asbestos material was utilised throughout the

construction phase. This material provided high tensile strength, insulation benefits, is of a fibrous

nature and a strong heat resistance component is exhibited by the mineral. Due to the versatile

nature of the product, asbestos was widely used in building and construction methods from the

1930’s until the mid-1980’s, when it was subsequently banned in New Zealand. Three principal

fibres: Chrysotile (white), Crocidolite (blue) and Amosite (brown) are present in the material and

have the potential to become harmful when airborne. Chrysotile is considered the least harmful of

the three fibrous components.

Prior to undertaking refurbishment of the Hamilton building, various alternatives were investigated

by PFR to facilitate business continuity requirements. These included the procurement of

alternative locations, and the construction of Building ‘F’ at 120 Mt Albert Road. In April 2012

4

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

recommendations were presented to the PFR board which included a refurbishment method of

vacating upper levels of the existing Hamilton building while asbestos removal and construction

was undertaken, progressing down to lower levels. This became the methodology for asbestos

removal and construction refurbishment activities.

Asbestos surveys have been conducted by

, on four separate

occasions, the most recent being January 2018. In a Survey report furnished in December 2014,

the significant presence of asbestos was highlighted throughout the Hamilton building. This

included, but was not limited to, spray coating and debris throughout areas such as ceiling voids,

risers, motor room, gaskets and pipework. A high degree of contamination was highlighted, with

the asbestos fibre type physically identified as friable and Chrysotile in nature. This report also

referenced the presumption of the presence of SP Crocidolite fibres throughout.

Construction and refurbishment of the Hamilton building commenced in early 2015 by

. Included in this contract was the removal of ACM from the Hamilton building and

adjoining Plant room. Areas including the lift shafts and Annex levels one and two were excluded

from the scope of this project – reason for this being that there was no refurbishment activity being

conducted in these areas at the time therefore presenting a low risk of contamination. The risk of

airborne asbestos fibres was considered low and the ACM used during construction was deemed

to be in a stable condition.

Removal of ACM began in the Annex Plant room, followed by the preferred methodology of clearing

the upper levels of the Hamilton building, then descending down levels as each floor was cleared

of asbestos. This reflected the document furnished to the PFR board in April 2012.

Focus on the removal of the ACM from the Plant room centred around the porous concrete cinder

block ceiling. Asbestos spray coating was removed from these blocks and remaining material that

could not be practically accessed was encapsulated using an asbestos binding compound. The

entire floor and walls of the Plant room were enclosed in black polythene sheets while the ceiling

was cleaned.

In July 2015, representatives of

conducted visual inspections and air

monitoring in the Plant room in accordance with accepted standards at the time. This occurred prior

to and immediately after the polythene sheeting was removed and was conducted using lighting

5

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

from torches, as electrical lighting was unavailable at that time. Initial asbestos tests included visual

and air monitoring procedures, followed by swab sampling conducted on the 1 July 2015. Two

swab tests produced positive results. Amosite fibre was located at the South end of the Plant room

and Chrysotile on the West side fire hose reel. Subsequent testing on the 6 July 2015 at these

locations produced negative test results.

Upon completion of the clearance procedures in July 2015 by

, contractor and staff

access to the Plant room was permitted in order for construction and installation of utilities to

commence. This included the installation of various plant, construction of walls and the instalment

of two galvanised flues from the Plant room through to the Annex ceiling inside a now sealed riser.

The asbestos removal and visual inspection report furnished by

on 1 July

2015, made reference to remaining asbestos fibres within the porous concrete cinder blocks and

in the gaps between these blocks. The porous nature of the blocks meant that it was impossible to

completely remove all asbestos fibres without removing the cinder block ceiling altogether.

Therefore, the ceiling was encapsulated with an ABC (Asbestos Binding Compound).

Further asbestos removal of the upper levels of the Hamilton building commenced mid-2015,

followed by the associated construction phase of the project

Previous to these activities, it is understood that asbestos removal and encapsulation had occurred

at the adjoining Cunningham building and the tunnel connecting the two buildings. Lagging

material was removed from the services within the tunnel and encapsulating paint product applied

to the external walls of the Cunningham building.

2.2. Incident

From July 2015,

continued removal of ACM from the principal Hamilton building

and the subsequent project refurbishment and construction followed the asbestos clearance at

various levels.

On 17 January 2018,

staff were instructed to commence survey work within the Annex

Building Plant room.

This request was made in order to reassure the PFR Site Manager of processes to date, before

continuing with the wider asbestos management survey.

6

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

The initial visual inspection of the Plant room indicated the presence of asbestos in numerous

locations. Seven swab tests in the Plant room confirmed Chrysotile asbestos fibres were located

in various areas including dust to pipe work, door frames, machinery and floor areas. Further to

this, five ACM samples were found in samples between the ceiling cinder blocks, on electrical

casing, on columns and walls. Two samples in the tunnel indicated Chrysotile spray coating debris

on the floor and walls of the Plant room.

As a result of this testing regime, Plant room access was restricted and a notification made to

Worksafe New Zealand.

As a result of the Plant room asbestos findings, further monitoring and testing was conducted at

various locations within the Hamilton building.

Three swab tests were conducted in the Ground Floor Lobby area. These tests produced a positive

result for Chrysotile asbestos fibres. On-going air monitoring was conducted and access to the

area restricted. This area had previously been cleared of ACM by

on 27

July 2015, allowing contractor and staff access to the area.

Removal of asbestos from the North Lift Motor room, level seven was initially outside of the scope

of work for asbestos removal because it was not part of the redevelopment work. Subsequent

activity in the motor room by various contractors later necessitated the cleaning of the North Lift

Motor room of asbestos.

provided an asbestos Removal Clearance

Certificate on 27 October 2017.

In January 2018, asbestos material was located between levels four and six of the Hamilton building

West Riser. This area was also the subject of earlier clearance and

had

completed cleaning in September and October 2015.

Asbestos in the form of sprayed ACM was located in the North lift Shaft between levels one and

four. Subsequently a swab in the North Lift produced a positive result and this area was restricted

to staff and contractors. PFR maintained regular air monitoring in this area and ensured on-going

Asbestos Surveys were conducted by

.

7

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

INVESTIGATION

3.1. Areas of Focus

The focus of this investigation has primarily been to establish the cause of contamination in the

Plant room and subsequent areas during the refurbishment and construction of the Hamilton

building.

Emphasis during the course of the enquiry has been placed on:

• The asbestos removal methodology

• Subsequent inspection reports

• Activity in the Plant room after asbestos clearance

• Further asbestos contamination within the Hamilton building

• Associated risk to PFR staff and Contractors

Outside of the primary focus has been any on-going asbestos discoveries resulting from further

Asbestos Survey Reports as this risk is considered negligible.

Where possible, all PFR personnel and associated Contractors have been interviewed. Refer

Appendix C – Investigator Jobsheet which contains details of interviews (including private

information).

have been provided a list of questions relating to their

involvement in the asbestos removal process. To date a response to these questions has not been

received from either party. Where possible, documents of a corroborative nature have been used

to support findings during the earlier stages of the investigation. This has necessitated the

requirement to draw some inferences where a supporting interview has not been conducted.

Past and current PFR staff have been interviewed about their involvement in the asbestos removal

process between 2014 and present.

have made available two principal

staff members for interview and have provided supporting documentation.

PFR staff interviewed include:

. Further interviews included

of

of

and

. Written interview questions were

provided to representatives of

and

.

8

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Supporting documents have been obtained from over 300,000 items sourced from

, PFR

key personnel mailboxes or provided to the enquiry by contributors. These have been filtered down

to 94 relevant documents which are now included in the document schedule (Appendix A). These

documents, along with interviews have provided the foundation of the findings.

3.2. Legislation

The revised

Health and Safety at Work Act 2015 and accompanying

Asbestos Regulations 2016

imposed new changes & have formed an important aspect of the investigation. Critical to this is

the overlapping responsibilities for management and staff to ensure all reasonably practicable

steps are taken in the risk management process. The Act supports a strong overall governance

model and the obligations by introducing the PCBU and Officer definitions. These are defined in

the Duty of Care responsibilities to ensure all business undertakings are accompanied by

influencing and mitigating risk factors.

The Act imposed changes in the risk management process, necessitating the requirement for the

PCBU (Plant and Food Research) to consult, co-operate and co-ordinate activities to mitigate risk

to all staff and contractors under the influence of the PCBU.

These fundamental health and safety activities require:

• The elimination of health and safety risk; or

• Minimising this risk through the implementation of controls, as far as is reasonably

practicable.

A PCBU must ensure so far as is reasonably practicable that the health and safety of other persons

is not put at risk from work carried out as part of the business of undertaking

A duty holder (or PCBU) obligations to manage risk are limited to doing what is in their ability to

control and manage, along with what is reasonably practicable for them to do to manage the risk.

This is potentially moderated if the cost imposed to actively manage this risk is disproportionate to

the outcome.

Applicable to PFR is the specialised nature of asbestos management. Managing this risk under the

new Act may include the on-going engagement of an asbestos specialist, to provide a proactive

9

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

and governing influence during the entire removal process. This is further reiterated by the nature

of the removal methodology and the need for business continuity.

The key question applicable to the change in legislation is:

What is known or ought to be reasonably known about the hazard associated with asbestos

removal and how effective are the current removal and containment processes in eliminating or

effectively controlling this risk?

The approved code of practice for asbestos removal further highlights the relevant point that if

asbestos material cannot be identified but the presence of such ACM is assumed through a

qualified professional, then this material must be considered identified and treated as such.

Further requirements by Worksafe New Zealand highlight the likelihood of asbestos containing

particles and dust to be disturbed or become airborne during routine work, and consequently the

risk to workers from exposure to this happening. The effectiveness of encapsulation material

becomes important during this activity must be assessed. There is a proactive requirement by the

PCBU and Officer to ensure compliance and obligations are met.

Sectio

ns 48 and 49 of the Health and Safety at Work Act 2015 highlight the ramifications of failure

to ensure compliance is actively directed and influenced by the PCBU.

3.3. Risk

Significant research has been conducted around the carcinogenic risk of asbestos, however on-

going studies have identified the often unpredictable nature of asbestos fibres through respiratory

exposure. The risk to individuals exposed to the fibres is complicated by an apparent latency period,

where associated disease such as Asbestosis and Mesothelioma may occur.

Asbestos is apparent to two groups – Serpentine Group, which consists of Chrysotile or ‘white’

asbestos and Amphibole which includes Crocidolite (Blue) and Amosite (Brown). Chrysotile

asbestos is considered the least harmful of the group, however recent studies have indicated this

is considerably influenced by such factors as smoking, signifying the original perception of a more

benign fibre may not accurately highlight the risk.

10

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Although presumptions were indicated that the PFR building contained all three types of asbestos

fibres, Chrysolite fibres are the dominant compound removed to date.

Between 16 January and 14 February 2018 extensive air monitoring was conducted. No airborne

asbestos fibres were detected.

Maintenance activities conducted in the Hamilton building Annex Plant room presented the greatest

risk to contractors and PFR staff (limited to those staff conducting these activities within the plant

room). The effectiveness of the encapsulation in this area, accompanied by the nature of the

installation and maintenance requirements has likely had a significant impact on asbestos

contamination identified in January 2018.

Encapsulation is considered a temporary resolution to remaining ACM’s and usually only

considered when it is not practical or cost prohibitive to remove all ACM.

In January 2018, external swabs were taken of all louvre doors of the Plant room to establish if

asbestos contamination from the migration of airborne fibres had occurred to the surrounding

areas. The results of these swabs were negative indicating contamination was isolated to the Plant

room, however the risk to contractors and staff cannot be discounted.

3.4. Timeline

A Sequence of Events has been prepared to support findings of this investigation and to provide a

quick reference to relevant ‘events’ during the material time. Refer Appendix B.

FINDINGS

Outcomes of this investigation have been based on interviews with key PFR staff and contractors.

have been furnished with a list of relevant questions relating to our

investigations, as has

. No response has been received to date from either party.

It is not anticipated however that their response will influence the outcomes of the investigation to

a large degree.

4.1. Alternative Options

Between October 2011 and June 2013 options were presented to the Board at Plant and Food

Research with regards to the refurbishment of the Hamilton building, 120 Mt Albert Road, Auckland.

11

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

At this time the building presented significant structural and operational concerns including the

deterioration of asbestos material, dated facilities and compliance considerations. Alternative

options to maintain business continuity are explored, including the lease of a substitute premises

and the construction of building ‘F’ onsite. In April 2012 recommendations are made to the Board

which incorporated continued use of the Hamilton building by the operational staff and conducting

refurbishment and renovations from the top two floors first and rehousing staff as construction

progressed downwards. Financial and operational considerations are presented with the Board

making a decision to proceed with the Hamilton Building being refurbished on a staged (floor by

floor) basis. With the benefit of hindsight, this decision may not have been the most effective.

(Document TC94 refers)

4.2. Removal Methodology

In March 2015 three Tender submissions were received by

for the removal and

disposal of asbestos material within the Hamilton building and Plant room.

were subsequently awarded this contract. The methodology for the removal of asbestos

was based on Asbestos Refurbishment Surveys completed by

in 2006

and 2010. The Program of Works for the building refurbishment provides further referencing for the

intended Removal Control Plan.

commenced asbestos removal and the Hamilton building Annex Plant room was

completed in June 2015. A subsequent Asbestos Removal Visual Inspection Report was submitted

to Arrow International after 6 July 2015, indicating no obvious asbestos debris or waste remaining.

Additional comments were made with regards to the asbestos remaining in the porous concrete

cinder blocks of the ceiling and the cracks between these blocks.

Asbestos removal processes then commenced in the West Riser and upper floors of the Hamilton

building.

On 26 February 2018,

of

was interviewed and outlined the current

adopted methodology around asbestos removal. Outlined during this interview is the adequacy of

the approach to this process, given it is primarily adopted around the refurbishment and

construction plan, rather than the significant asbestos consideration. Indications are presented that

the asbestos methodology should be developed as a priority to avoid the current issues around

subsequent asbestos contamination.

12

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

(Document TC01, TC03, TC11, TC08, TC62, Interview

, Interview

refers)

4.3. Role Definition

In 2014, and over the subsequent three years, the role of Site Manager at PFR was performed by

. Over this time numerous considerations are given towards the risk to PFR staff

and contractors during the asbestos removal process from the Plant room and subsequently the

Hamilton building. These considerations are evident by the engagement of

in July

2014, and intermittently during this period. Email exchanges between the principal entities involved

in refurbishment and asbestos removal indicate a lack in specific role definition and clarity.

Ownership and responsibility for overall risk management of the removal process indicates a

disconnect between PFR, the construction principal and asbestos removal contractors.

This is further highlighted by ACM discoveries and contamination as the project progresses. Areas

outside the Scope of Work become relevant during removal and these issues are raised as they

are presented and do not feature in any overarching governance document. Incidents occurred

where up to three attempts were made to achieve clearance of specific areas, indicating a lack in

consistency in approach to the adopted methodology.

(TC58, TC09 1-3, TC21, TC22, TC25, TC27, TC28, TC58, TC60, TC71, TC74 Interview

, Interview

refers)

4.4. Intermittent engagement of expert

are considered by many in the asbestos industry as a pre-eminent authority in the

removal and management of asbestos in New Zealand.

is considered an expert in

his field and his qualifications and experience have been gained over a 35 year industry career.

During initial stages of removal at PFR, he was engaged in an ad hoc capacity, often remotely, to

provide advice to PFR staff and contractors.

provide experienced and qualified surveyors, with an IANZ accredited lab

facility. The surveys are conducted following Good Practice guidelines published by WorkSafe NZ.

Air Monitoring, visual inspections and surface swab testing were performed by this organisation

on-site at PFR.

Contractor methodology was based on Asbestos Survey Reports provided by

. The unique requirements for a business continuity capacity in the Hamilton building

13

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

presented perpetual challenges. In order to successfully overcome these and avoid ongoing issues,

a holistic methodology was required to guide contractors throughout the entire process.

(TC62, TC03, TC11, TC37, Interview

refers)

4.5. Progressive Scope of Work

As outlined earlier in this report, a site-specific Scope of Work document for the removal of asbestos

during the PFR refurbishment contract has not been identified. Activities around further asbestos

discovery and contamination was of a reactive nature. The qualitative benefits of a document

providing a progressive scope of work for removal contractors has become apparent over the

course of the investigation. As contractors have progressed in this project, further asbestos issues

have arisen through areas outside the initial scope of work but significant in the mitigation of risk.

Influencing factors again include the construction requirements around PFR staff’s on-going

operational requirements. Contractor experience with projects of this nature is an important

consideration. This is reiterated through recurring asbestos contamination and further discovery of

ACM’s. With consideration to legislative requirements at the time the project commenced, a

proactive governance document, with a progressive scope of work capacity was not in existence.

(Documents TC24, TC25, TC33 refer)

4.6. PFR Response

Plant and Food Research have progressed considerably to ensure obligations under the Health

and Safety at Work Act are adhered to. This has primarily occurred since the appointment of a

proactive PFR Site Manager, resulting in the current issues highlighted since January 2018. The

implementation of a robust air monitoring regime during construction and asbestos removal is

accompanied by further Asbestos Surveys of a more vigorous and in-depth nature than documents

provided in 2006, 2010 and 2014. A transparent and informed approach has been adopted for staff

around the mitigation of risk associated with airborne asbestos fibres, complemented by further

engagement of a recognised asbestos expert. Responsibilities have been accepted at an Officer

level, under the Act. PCBU duty of care obligations to ensure all steps that are reasonably

practicable are taken to mitigate risk are complemented by strong input from Health and Safety

representatives onsite in the form of a parallel investigation into the recent contamination incident.

This is demonstrated by the Asbestos Management Plan review processes, utilising external expert

advice to incorporate crucial elements such as Trigger Response Action Plans.

14

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

The recent appointment of a PFR Site Manager who has undertaken the specific responsibilities of

the refurbishment project has seen a more direct approach to asbestos removal activities and helps

address the overlapping contractor accountabilities of the PCBU. Something that has been

previously absent. The due diligence of the PCBU includes activities conducted by contractors and

responsibilities include policy and planning, monitoring and reviewing.

(Documents TC02, TC03, TC04, TC11, TC25, TC64, TC69, TC81, TC84, TC87 refer)

4.7. Site specific risk assessment

A document produced by

and furnished to PFR in July 2014 highlighted the

recommendation around the use of power tools such as hammers, drills and sanders in the Plant

room. With the requirement for ongoing installation and maintenance, a task specific risk

assessment was recommended.

Between June 2015 and November 2018 PFR staff and contractors entered the plant room on thirty

documented occasions to conduct significant installation, repairs and maintenance.

Risk mitigation during the refurbishment of the Plant room does not appear to have been an

established process. This is also evident in subsequent areas within the Hamilton building,

including the 7th floor Lift Motor room, Risers and Ground Floor Lobby. Since the discovery of

asbestos contamination in January 2018, this has been addressed, however the risk to workers in

this area should not be underestimated as the project progresses.

(Documents TC93 TC28, TC61, Interview

refer)

RECOMMENDATIONS

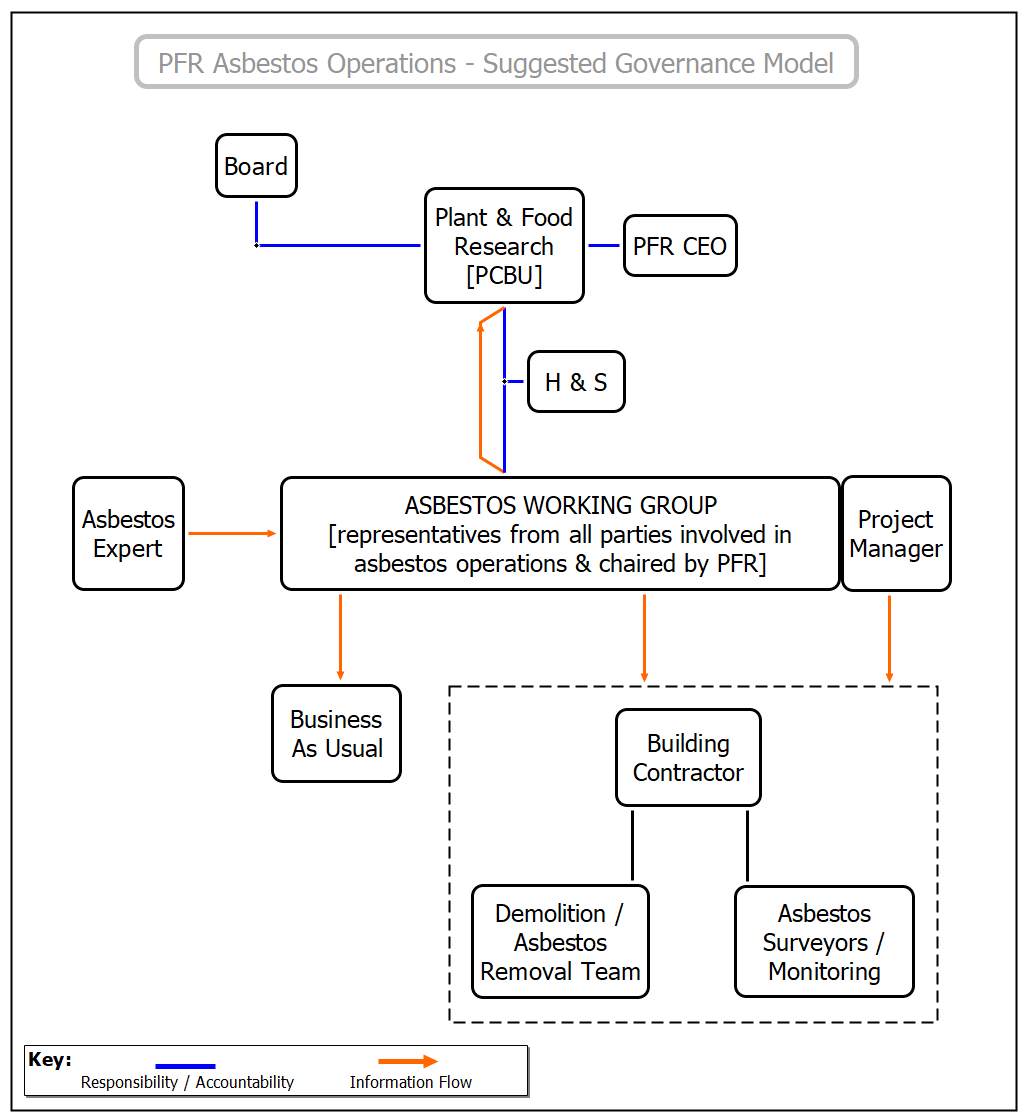

Recommendation 1:

Establishment of an overall governance approach to on-going asbestos removal processes to

ensure obligations are adhered to under HSAW Act 2015. Asbestos operations are significant

enough to warrant the establishment of a working group and governance throughout the remainder

of the project. In retrospect, this would have been ideally implemented throughout the entire project

or at least since publication of the 2014 survey. Although not legally obligated until 2016, the

discovery in 2014 that asbestos presence throughout the Hamilton building was more significant

than originally scoped and warranted a more active role by PFR.

15

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

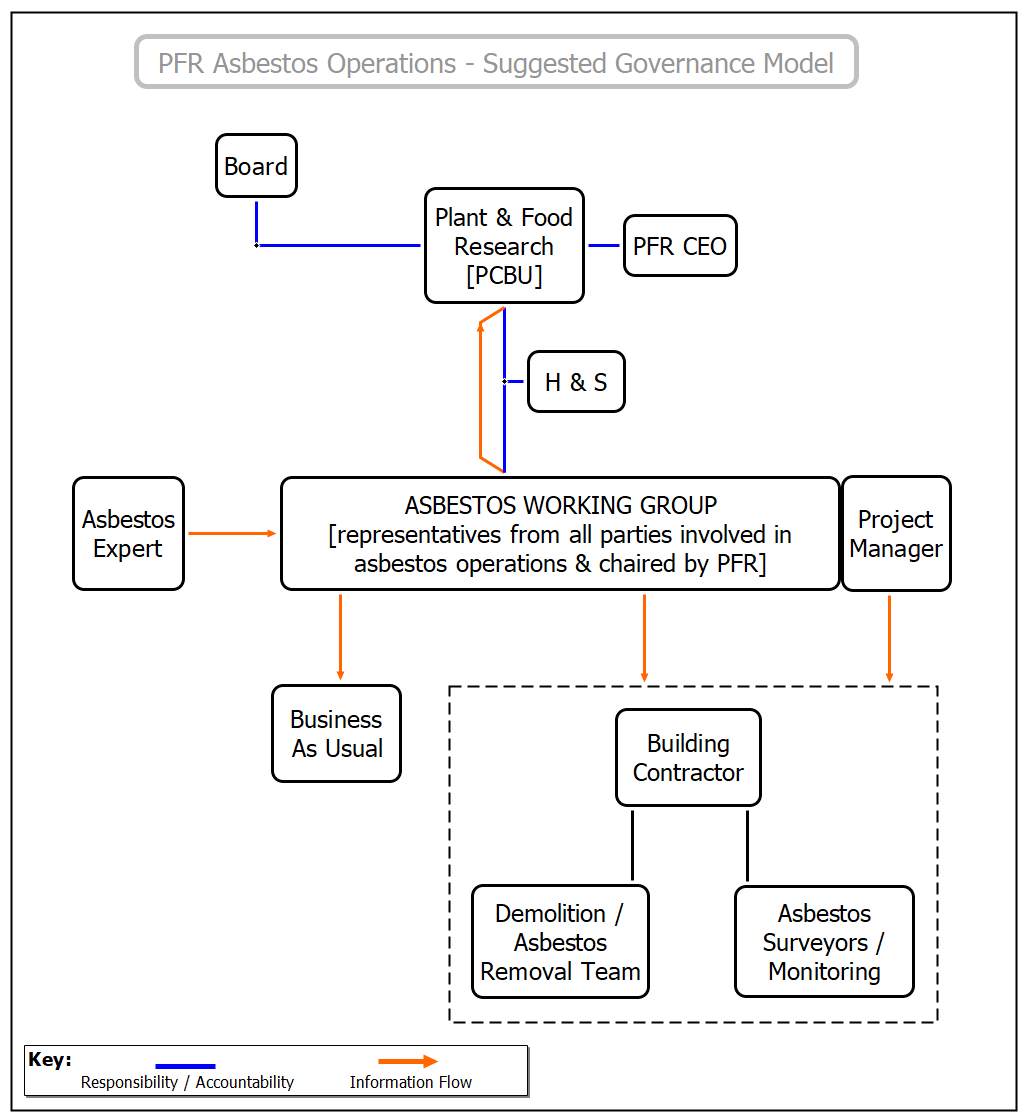

See Figure 1 below as a suggested model:

Figure 1

Recommendation 2:

Whilst a recently established Asbestos Discovery Incident Response Team ensures current health

and safety obligations are adhered to, this is of a reactive nature. A proactive approach was

required to be implemented considering the new legislative requirements on 01/04/2016. This

would have ensured a mitigated response to the current asbestos issues. By following the

guidance of a recognised asbestos authority, the subsequent issues associated with entity silos

16

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

may have been significantly allayed. This guidance would have ensured processes such as review

of encapsulation, Worksafe guidelines around encapsulation methods, Site Specific Reviews and

overall direction from the assigned Project Manager.

Recommendation 3:

Engagement of an asbestos expert to ensure continual improvement methodology is implemented

and direct involvement during further removal stages of cleaning and clearing ACM’s. This is

recommended to occur through all stages of the project, from planning, through operational

removal, to final clearance. Increased staff and contractor awareness around current risks

associated with the use of items such as power tools and migratory fibre contamination should be

incorporated in this engagement process.

Recommendation 4:

Ongoing robust clearance process. Since the discovery of ACM in the Plant Room, detailed

Asbestos Clearance reports have been furnished by

. The content of recent

reports (30/01/2018) is significant when compared with earlier Surveys (05/12/2014), although

considered best practice at the time. The earlier report gives little focus towards remaining ACM’s

in the Plant room, with a total of three tests conducted, two of which were repeated after a positive

asbestos result. When considered with the recent Survey, which contains significant visual and

swab testing results, priority should be placed on similar clean and clear processes. This is

particularly relevant given the contractor activity in the Plant room after

had provided a clearance report.

Recommendation 5:

The implementation of a robust Contract review process to ensure adequate experience is

demonstrated during the procurement stages of future projects, particularly when unique

undertakings are existent. This review may include the ability for contractors to demonstrate

adequate site-specific risk assessments with asbestos removal and experience in unique and

challenging removal processes.

17

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

CONCLUSION

In 2015, significant changes to the Health and Safety at Work Act were implemented into the

workplace on 01 April 2016. This along with the Asbestos Regulations 2016 and concurrent

Worksafe New Zealand guidelines have formed a significant element in the findings of this

investigation.

When removal of asbestos commenced in the Hamilton building plant room during the latter part

of 2014 and 2015, it is evident PFR have met their obligations under the governing legislation at

the time, The Health and Safety at Work Act 2015.

Changes in 2016 have required a contemporaneous approach to be implemented with matters

pertaining to Health and Safety. This has not initially been evident with the asbestos removal

conducted at Plant and Food Research. As the project has progressed, on-going isolated incidents

have seen a reactive response to risk mitigation, without a consistent approach by the duty holder

through resources and process.

It is important to acknowledge that even without the existence of a Health and Safety incident,

governing management with the ability to exercise significant influence over the business or

undertaking,

e.g. a Chief Executive, holds a responsibility. This does not become discharged and

the duty does not transfer to those who are merely advising or making recommendations.

There have been a number of broad factors that have led to asbestos contamination during the

refurbishment of the Hamilton building. With information available at the time, the decision to

progress with a floor by floor removal and refurbishment methodology was considered the more

efficient way of performing these operations and was endorsed by the Board. However, this has

resulted in a reduced consideration of the significance towards asbestos removal requirements and

indicated a priority on the construction and business continuity requirements.

With legislative changes to health and safety and asbestos management, there is no evidence that

these changes were accompanied by clear and consistent management ownership during the

asbestos project. Accompanied by a high staff attrition rate within the construction contractor, these

factors along with findings already specified have contributed to the lack of sufficient risk

management processes, resulting in further contamination.

18

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

Thompson & Clark Investigations Ltd Plant & Food Research

CONFIDENTIAL

That said, it is important to reiterate the risk throughout the project has been considered, and

assessed, as low.

It is apparent that no blame can be directed to a single party or individual and a catalogue of issues

over a significant period of time have contributed to the contamination incident. Adoption of the

recommendations set out in this report would prevent further health risks occurring through

asbestos contamination during future refurbishment operations.

19